Hydraulics use pressurized fluid to create precise movement and high force in machinery, ideal for complex tasks like lifting or manufacturing. Propeller systems, on the other hand, convert engine power into thrust for moving watercraft or aircraft, offering simplicity and reliability. While hydraulics provide control and efficiency, propellers focus on straightforward propulsion. To understand which system suits your needs best and how they compare in detail, keep exploring further.

Key Takeaways

- Hydraulics use pressurized fluids for precise, high-force movements; propellers convert rotational energy into thrust for propulsion.

- Hydraulics offer high control and accuracy, while propellers provide straightforward, reliable thrust with less nuanced control.

- Hydraulics are more complex, requiring pumps and fluids, whereas propeller systems are simpler and easier to maintain.

- Hydraulics excel in applications needing precise positioning and heavy lifting; propellers are ideal for marine propulsion and basic thrust.

- Mechanical efficiency varies; hydraulics minimize energy loss with proper maintenance, while propellers face resistance-related energy losses.

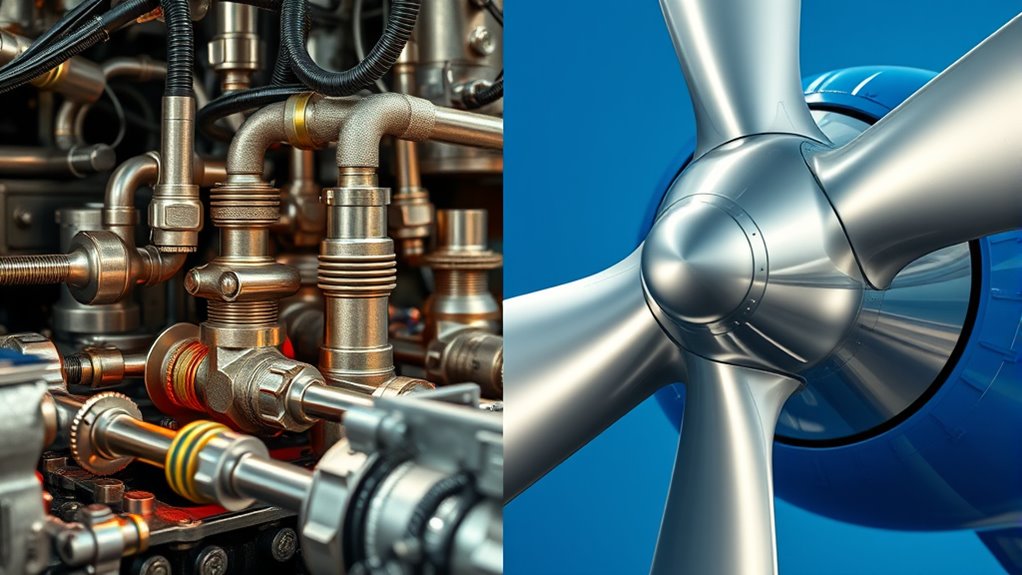

When choosing between hydraulics and propeller systems for marine or industrial applications, understanding their core differences is essential. These systems operate on distinct principles, affecting how they deliver power and control. Hydraulics rely on fluid pressure to transfer energy, using pressurized liquids to move mechanical components precisely. This fluid pressure enables smooth, controlled movements and is especially valuable when requiring high force within compact spaces. Propeller systems, on the other hand, function by converting rotational energy into thrust, typically via engines driving blades through water or air. They’re straightforward in design, making them reliable and easy to maintain.

Hydraulics offer precise control and high force in compact spaces compared to simpler, reliable propeller systems.

One key distinction lies in their mechanical efficiency. Hydraulics tend to have high mechanical efficiency because they can transmit force over long distances with minimal energy loss, especially when designed properly. The efficiency hinges on reducing friction within the hydraulic fluid and minimizing leaks. This means you get more consistent power delivery, which is crucial for applications demanding precise control, such as lifting heavy loads or operating complex machinery. Conversely, propeller systems are generally less mechanically efficient due to energy losses from water or air resistance and the mechanical friction of moving parts. Still, they excel in delivering direct thrust, making them ideal for propulsion in ships and boats.

Fluid pressure in hydraulic systems offers you the advantage of fine-tuned control. When you need to adjust movements smoothly or hold a position steadily, hydraulics shine. They can generate substantial force with relatively small actuators, allowing you to design compact machinery that’s still powerful. This precise control benefits industrial applications like manufacturing presses or heavy-duty loaders, where accuracy and force are crucial. Propeller systems, however, are more suited for situations where straightforward thrust is sufficient, like propelling a vessel forward. Their simplicity translates into fewer points of failure and easier maintenance, which is why they’re the go-to choice for marine propulsion.

While hydraulics provide versatility and precision, they require a hydraulic fluid, pumps, and reservoirs, which can increase complexity and maintenance needs. Propeller systems, by contrast, are mechanically simpler but less adaptable for nuanced control tasks. When choosing between them, consider your application’s demands for fluid pressure management and efficiency. If you need tight control and high force in confined spaces, hydraulics are likely your best option. For straightforward propulsion with minimal fuss, propeller systems deliver reliable, efficient performance. Understanding these core differences helps you make informed decisions that align with your operational goals, ensuring you select the right system for your specific needs.

Frequently Asked Questions

How Do Maintenance Costs Compare Over the Lifespan of Each System?

You’ll find hydraulics generally have higher maintenance costs over their lifespan due to more complex components that require regular inspection and replacement. Propeller systems tend to be more cost-efficient because they’re simpler, with fewer parts prone to wear. However, hydraulics often offer greater reliability in demanding conditions, reducing unexpected repairs. Overall, your choice impacts long-term maintenance costs, balancing initial expenses, reliability, and ongoing upkeep.

Which System Offers Better Performance in Extreme Weather Conditions?

You’ll find hydraulics generally perform better in extreme weather, especially with ice resistance, as they can be more adaptable to cold conditions and resist freezing issues. Propeller systems, however, may face vibration effects and ice buildup that impair performance. So, if you’re dealing with icy or turbulent environments, hydraulics tend to offer more reliable operation, ensuring safety and efficiency despite challenging weather conditions.

Are There Environmental Impacts Associated With Hydraulics Versus Propeller Systems?

You’ll find that hydraulics often have a larger environmental footprint due to oil-based fluids, which pose risks of leaks and contamination. Propeller systems usually have a smaller resource sustainability impact since they rely on mechanical parts and less hazardous materials. By choosing a propeller system, you reduce potential environmental harm, supporting resource sustainability and lowering ecological risks associated with hydraulic fluid leaks.

How Do Installation Complexities Differ Between the Two Systems?

You’ll find that hydraulics pose more installation challenges due to their complex components and fluid connections, making integration more difficult. Propeller systems are generally simpler to install because they involve straightforward mechanical parts and fewer connections. With hydraulics, you may encounter integration difficulties related to space, plumbing, and ensuring proper sealing. Overall, hydraulics require more planning and expertise during installation, while propeller systems tend to be quicker and easier to set up.

What Are the Safety Considerations Unique to Each System?

You should prioritize hydraulics safety by regularly inspecting lines for leaks and ensuring proper fluid containment to prevent fires or hydraulic failure. For propeller safety, maintain clear zones around moving blades and implement safety covers to prevent accidents. Both systems demand diligent safety measures—hydraulics safety focuses on fluid handling, while propeller safety emphasizes physical protection. Staying vigilant helps avoid injuries and system malfunctions in either case.

Conclusion

So, it’s almost funny how hydraulics and propeller systems seem to complement each other, like they were meant to coexist. While hydraulics offer precise control, propellers deliver raw power—each system has its moment in the spotlight. Whether you’re choosing based on efficiency or versatility, remember, sometimes the best solution comes from unexpected combinations. After all, it’s no coincidence that both have shaped the way we move through water and air.