To stop splash-out before it starts, you need to properly size your surge tank based on your system’s pressure fluctuations, flow rates, and surge potential. Guarantee the tank volume buffers pressure surges and minimizes fluid ejections by analyzing maximum flow changes and positioning it close to high-risk zones. Correct sizing prevents damage, reduces downtime, and improves safety. Keep in mind that mastering these concepts will help you optimize your system’s safety and performance.

Key Takeaways

- Analyze maximum flow rate changes and pressure spikes to determine the required surge tank volume.

- Place surge tanks near high-pressure zones, pump stations, or bends where surges are most likely to occur.

- Incorporate baffles or flow diffusers within the tank to evenly distribute flow and reduce splash-out.

- Properly size tanks based on fluid velocity, pressure fluctuations, and system dynamics to prevent over- or under-sizing.

- Regularly inspect and maintain surge tanks and their components to ensure effective pressure damping and minimize splash-out risks.

Understanding the Role of Surge Tanks in Fluid Systems

Surge tanks play a essential role in maintaining stability within fluid systems by absorbing pressure fluctuations caused by sudden changes in flow or operating conditions. When flow rates increase or decrease abruptly, pressure waves travel through pipes, risking damage or system failure. The surge tank acts as a buffer, providing a space where excess pressure can dissipate safely. It helps prevent water hammer, reduces stress on pipes and valves, and guarantees smoother operation. By stabilizing pressure, surge tanks improve system reliability and extend equipment lifespan. They are especially critical in high-flow or high-pressure systems, where rapid changes are common. Properly sizing these tanks ensures they can handle expected pressure surges, keeping your system safe, efficient, and resilient during fluctuating conditions. Headphones, such as those with Bluetooth connection, can be used to monitor and troubleshoot system audio during maintenance, ensuring optimal performance.

Causes and Consequences of Splash-Out During Surges

When pressure waves rapidly pass through a fluid system, splash-out occurs when the fluid is forcefully expelled from the surge tank, often due to insufficient capacity or improper design. This sudden expulsion happens because the tank can’t absorb or dampen the pressure change effectively. Causes include undersized tanks, poor inlet/outlet configurations, or rapid flow fluctuations. The dynamic contrast ratios of the system can further influence how quickly and intensely pressure changes occur. The consequences are significant: fluid loss, equipment damage, and system instability. Splash-out can lead to operational downtime, increased maintenance costs, and safety hazards. It also causes system inefficiencies, as the fluid loss may require additional refilling or repairs. Understanding these causes helps you prevent splash-out by ensuring proper tank sizing and design, ultimately maintaining system stability and avoiding costly interruptions.

Key Factors Influencing Surge Tank Capacity Selection

When selecting a surge tank capacity, you need to consider how system pressure fluctuates during operation. Fluid velocity impacts the surge volume you require, affecting how quickly pressure changes occur. Additionally, your response time to operational shifts plays a vital role in ensuring the tank can handle pressure surges effectively. Incorporating total‑cost clarity into your planning can also help optimize long-term maintenance and operation costs.

System Pressure Dynamics

System pressure dynamics play a crucial role in determining the appropriate surge tank capacity, as fluctuations in pressure directly impact system stability and safety. When pressure drops or spikes suddenly, the surge tank absorbs these changes, preventing damage and maintaining consistent flow. If the system operates at high pressures, the surge tank must accommodate rapid pressure variations to avoid system fatigue or failure. Conversely, in low-pressure systems, the tank helps buffer minor fluctuations that could cause cavitation or flow disruptions. Understanding the pressure profile throughout your system enables you to select a surge tank with the right volume and venting features. Proper sizing ensures the tank effectively dampens pressure swings, providing a stable environment and prolonging equipment lifespan. Additionally, AI-driven analytics can assist in predicting pressure fluctuations, enabling more precise surge tank sizing and improved system resilience.

Fluid Velocity Impact

Fluid velocity substantially influences the sizing of a surge tank because high flow rates can cause rapid pressure changes and turbulence within the system. If velocity is too high, it increases the risk of water hammer and splash-out, forcing you to size the tank larger than necessary. Keeping flow velocities within recommended limits reduces these risks and ensures system stability. Additionally, understanding AI in Education developments can help optimize system monitoring and control strategies for surge tanks.

Operational Response Time

Operational response time plays a critical role in determining the appropriate surge tank capacity because it directly affects how quickly the system can adapt to pressure changes. If your system responds rapidly, you’ll need a smaller surge tank since it can handle pressure fluctuations promptly. Conversely, slower response times demand a larger tank to prevent pressure surges from causing damage or splash-out. You should evaluate how quickly your control valves, pumps, and other components react to pressure variations. An inadequate response time increases the risk of system instability, so selecting a surge tank that aligns with your equipment’s responsiveness is essential. By understanding your system’s reaction speed, you can size your surge tank more accurately, ensuring effective pressure management and minimizing splash-out risks.

Calculating the Required Surge Tank Volume

To accurately determine the required surge tank volume, you need to analyze the potential flow variations and pressure fluctuations within your system. Start by identifying the maximum expected flow rate changes and pressure spikes during normal operation and transient events. These fluctuations will inform how much volume the surge tank must accommodate to prevent water hammer and pressure surges. Consider the system’s operational parameters, such as pump startup and shutdown cycles, as well as any sudden demand shifts. Use these data points to estimate the total volume needed to absorb pressure variations safely. Remember, the goal is to guarantee the surge tank can handle the worst-case scenario without causing splash-out or system instability. Additionally, understanding the system’s stability and how it responds to pressure changes is essential for effective surge tank sizing and system reliability. Accurate calculations here are vital for effective surge tank sizing and system reliability.

Common Methods and Formulas for Sizing Surge Tanks

| Method | Complexity | Typical Use Case |

|---|---|---|

| Empirical Formula | Low | Basic systems, quick estimates |

| Hydraulic Momentum Approach | Moderate | Moderate complexity systems |

| Dynamic Simulations | High | Complex, high-pressure systems |

Choose based on system needs and available data.

Practical Considerations for Surge Tank Placement and Design

When choosing where to install your surge tank, you need to ensure strategic locations that minimize pressure fluctuations and system disruptions. You also want to consider the tank’s dimensions are optimized for your system’s flow rates and space constraints. Proper placement and sizing can significantly improve system stability and efficiency. Additionally, understanding wiring basics can help ensure the system’s electrical components are safely and effectively integrated with your surge tank setup.

Strategic Location Selection

Have you ever wondered how the placement of a surge tank can greatly influence a pipeline system’s stability and efficiency? Strategic location selection is vital. Placing the tank near high-pressure zones helps absorb pressure surges effectively. Positioning it downstream of control valves or pump stations minimizes water hammer risks. Additionally, situating the tank where maintenance access is easy reduces downtime and safety concerns. Visualize the tank sitting just above a pump station, ready to catch sudden pressure spikes, or tucked close to a bend where surges are most likely. Proper placement ensures quick response times and better system performance. Remember, the right location isn’t just about convenience—it’s about optimizing flow stability and protecting your entire pipeline network. Proper placement can also benefit from understanding best anime movies and their storytelling techniques, which emphasize the importance of strategic planning and timing.

Optimal Tank Dimensions

Choosing the right dimensions for a surge tank is essential to guarantee it effectively absorbs pressure fluctuations without wasting space or resources. You should base your tank size on the system’s flow rates and pressure variations. A tank that’s too small won’t handle quick surges, risking overpressure, while an oversized tank wastes materials and space. Consider the flow velocity, fluid properties, and system dynamics to determine *ideal* height and diameter. Generally, taller tanks provide better pressure control, but width must accommodate flow rates without causing turbulence. You also need to account for space constraints and maintenance access. Properly sizing your surge tank ensures system stability and enhances overall performance. By carefully balancing these factors, you *assure* your surge tank provides reliable protection without unnecessary complexity or cost. Properly sized tanks improve system stability and longevity.

Best Practices to Prevent Splash-Out and Maintain System Safety

Implementing effective design and operational practices is essential to prevent splash-out and guarantee system safety in surge tank applications. You should ensure the tank’s inlet and outlet pipes are strategically positioned to minimize turbulence and splashing. Using baffles or flow diffusers can help distribute flow evenly, reducing violent splashes. Regularly inspecting and maintaining the tank’s internal components keeps conditions ideal, preventing blockages or damage that could cause overflow. Additionally, controlling flow rates and pressures ensures the system operates within safe limits, reducing the risk of splash-out. Visualize calm, steady flows entering the tank, smooth internal surfaces guiding liquids gently, and pressure gauges indicating safe operating conditions—all working together to prevent splash-out and maintain system safety. Incorporating maintenance protocols can further enhance system reliability, ensuring components function optimally over time.

Monitoring and Maintenance to Ensure Surge Tank Effectiveness

To guarantee your surge tank continues to perform effectively, consistent monitoring and maintenance are essential. Regular inspections help identify signs of corrosion, wear, or buildup that could compromise tank performance. Check for leaks, sediment accumulation, and proper water levels, ensuring the tank operates within design parameters. Maintenance tasks include cleaning filters, replacing worn components, and verifying instrumentation accuracy. Keeping detailed records of inspections and repairs aids in tracking tank health over time. Additionally, ensure safety devices like pressure relief valves function correctly. By staying proactive, you prevent unexpected failures and extend your surge tank’s lifespan. Implementing a routine schedule for monitoring and maintenance not only safeguards your investment but also maintains system stability, reducing the risk of splash-out and operational disruptions.

Case Studies: Successful Surge Tank Sizing in Various Industries

Effective surge tank sizing is demonstrated through a variety of real-world examples across different industries. In chemical plants, properly sized tanks prevent pressure surges that could damage equipment or cause spills. In oil refineries, surge tanks absorb sudden flow changes, maintaining stability during high-demand periods. In water treatment facilities, correctly designed tanks minimize splash-out and ensure smooth flow management. Imagine:

- A chemical process with a surge tank that curbs pressure spikes, protecting sensitive reactors.

- An oil pipeline system with a tank that stabilizes flow during rapid start-ups and shut-downs.

- A water plant with a tank that prevents overflow and reduces noise during fluctuating demand. These case studies show that understanding your process needs and applying precise sizing techniques can make all the difference in operational safety and efficiency.

Frequently Asked Questions

How Does Ambient Temperature Affect Surge Tank Performance?

Ambient temperature impacts your surge tank performance by affecting the fluid’s density and vapor pressure. As temperatures rise, the fluid expands, increasing the risk of splash-out and overflow. Conversely, lower temperatures cause contraction and may lead to increased pressure within the tank. You should account for these variations by adjusting tank size and venting systems accordingly, ensuring ideal performance and preventing splash-out during temperature fluctuations.

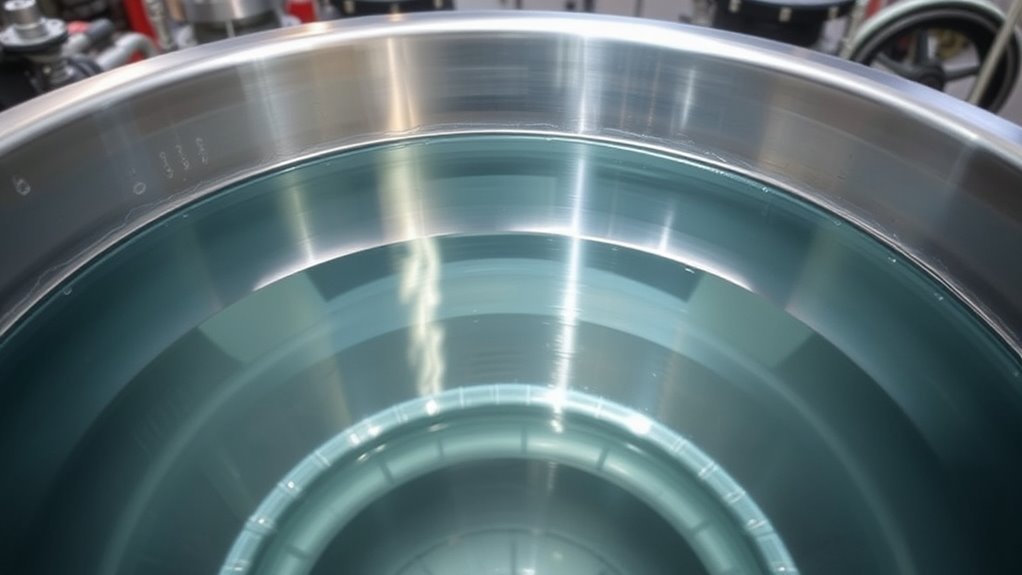

What Materials Are Best for Surge Tank Construction?

Think of your surge tank like a sturdy fortress—stainless steel, reinforced polymers, and high-grade composites stand out as top choices. These materials resist corrosion, handle temperature swings, and endure chemical exposure, keeping your tank reliable longer. You want something tough, like a knight’s armor, that won’t warp or degrade over time. Selecting the right material guarantees your surge tank performs effectively, preventing splash-out and maintaining system stability.

Can Surge Tanks Be Integrated With Automation Systems?

Yes, surge tanks can be integrated with automation systems. You can connect sensors to monitor water levels, pressure, and flow rates, allowing your control system to adjust operations automatically. This integration helps prevent overflow or dry running, enhances safety, and improves efficiency. By using programmable logic controllers (PLCs) or SCADA systems, you gain real-time data and automated responses, ensuring ideal surge tank performance and minimizing manual intervention.

How Do System Pressure Variations Influence Tank Sizing?

You need to account for system pressure variations because they directly impact tank sizing. Higher pressure fluctuations mean your tank must accommodate rapid volume changes without overflow or splash-out. Adjust your tank size accordingly, ensuring it can handle peak pressure scenarios. By designing for these variations, you prevent splash-out, maintain system stability, and improve overall safety and efficiency, especially during sudden pressure surges or drops.

What Are the Environmental Considerations for Surge Tank Installation?

You should consider environmental factors like temperature fluctuations, corrosion potential, and seismic activity when installing a surge tank. These conditions can affect tank durability and safety. To visualize, imagine the tank as a shield against weather and ground shifts. By selecting corrosion-resistant materials, ensuring proper insulation, and anchoring it securely, you help prevent leaks, failures, and environmental contamination, creating a safer, more reliable system.

Conclusion

By properly sizing your surge tank, you’re not just preventing splash-out—you’re safeguarding your system’s future. Think of it as a shield that protects your operations from chaos and costly damages. When you invest in the right capacity, you’re choosing stability over chaos, control over catastrophe. Don’t let splash-outs catch you off guard; instead, build a resilient system that stands strong against the unpredictable forces of fluid surges.