To achieve a seamless water sheet, you need to select high-quality, precision-engineered materials and carefully control water flow to prevent ripples or bubbles. Use sturdy frameworks for support, and verify surfaces are thoroughly prepared with cleaning and priming for better adhesion. Advanced tools like CNC machines, laser cutting, and flexible edging help create perfect seams. Keep in mind that combining these techniques will guide you toward flawless, smooth water sheets—stick around to learn more.

Key Takeaways

- Maintain precise water flow control to produce uniform, ripple-free water sheets.

- Use high-quality, smooth substrates and proper surface treatments for seamless bonding.

- Employ tools like squeegees or brushes to smooth surface imperfections during shaping.

- Utilize advanced technologies such as CNC machining and laser cutting for exact edges.

- Provide sturdy, well-aligned support frameworks to prevent warping and ensure stability.

Chef’sChoice 15XV EdgeSelect Professional Electric Knife Sharpener with 100-Percent Diamond Abrasives and Precision Angle Guides for Straight Edge and Serrated Knives, 3-Stage, Gray

CONVERT YOUR KNIVES: Ideal for converting traditional 20-degree factory edges of household knives into high performance Trizor XV...

As an affiliate, we earn on qualifying purchases.

Selecting the Right Materials for a Flawless Edge

Choosing the right materials is essential for achieving a flawless edge. You want materials that are durable, compatible, and easy to work with. Start by selecting high-quality substrates that won’t warp or crack over time. Precision-engineered sheets or panels ensure a smooth, even surface, reducing the risk of imperfections. Use adhesives that bond well without causing warping or bubbling; specific formulations are designed for seamless application. Consider surface treatments or primers that enhance adhesion and improve finish quality. Avoid low-grade materials that can compromise your work’s integrity. When you choose the right combination of materials, you set a solid foundation for a perfect edge. The right materials make your craftsmanship easier and help you achieve a seamless, professional look every time. Incorporating best oils for deep frying on keto diet can also enhance your work by providing healthier options for finishing or preparing materials where applicable.

Presto 08800 EverSharp Electric Knife Sharpener, 2-Stage System, Silver/Black

Sharpen kitchen and sport knives to a razor-sharp edge fast and economically.

As an affiliate, we earn on qualifying purchases.

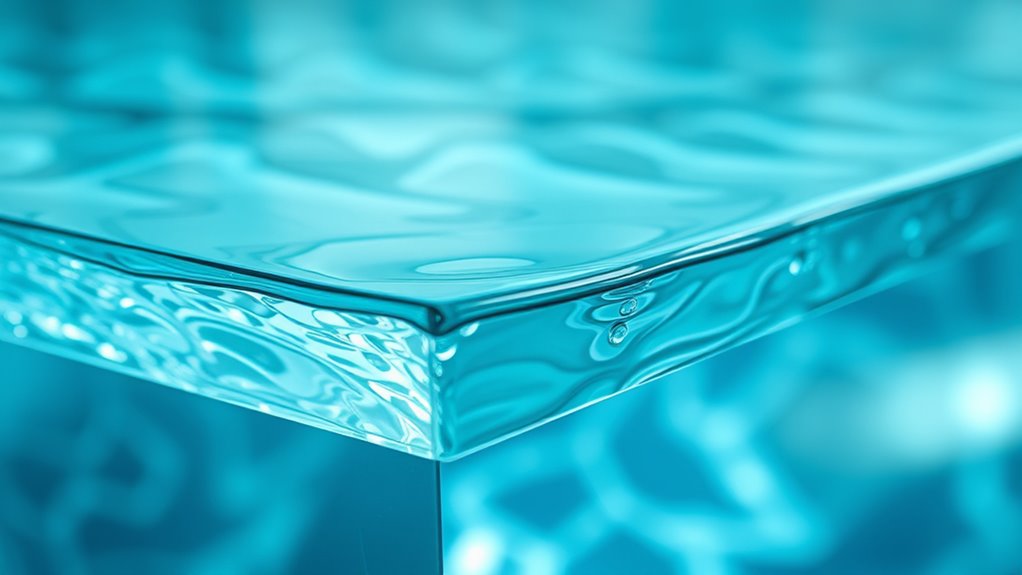

Precision Techniques in Crafting Water Sheets

After selecting high-quality materials, mastering precise techniques in crafting water sheets guarantees a flawless edge. You need to control every movement and angle carefully to assure smooth, even flows. Start by adjusting the water pressure and flow rate to avoid splashes or uneven sheets. Use steady, deliberate hand movements to guide the water, maintaining consistent speed. Focus on these key techniques: *Maintain a steady hand and consistent speed to prevent ripples.* *Adjust the water flow precisely for a uniform sheet thickness.* *Use tools like squeegees or brushes to smooth out imperfections.* Additionally, understanding water flow dynamics can help optimize your technique for a seamless finish.

Electric Knife Sharpener for Kitchen – Professional 3-Stage 100% Diamond System with 20° Precision Angle, Fast Sharpening to Restore & Polish Chef Knives(Black)

Revives Dull Knives Quickly — Easy & Forgiving for Home Use. Restore dull kitchen knives to clean, usable...

As an affiliate, we earn on qualifying purchases.

The Role of Structural Support and Framework

A sturdy framework is essential for maintaining the integrity and precision of your water sheets. It provides the necessary support to keep the material stable during shaping and application. Without a solid structure, even slight shifts can cause imperfections or uneven edges. You need a reliable skeleton—often made from metal or rigid wood—that can withstand tension and weight. This framework ensures your water sheet stays aligned and maintains the correct curvature as you work. It also helps distribute stress evenly, preventing warping or cracking. Properly constructing your framework creates a stable environment for detailed adjustments, making sure your water sheet remains flawless from start to finish. Ultimately, a strong support system is the foundation for achieving that seamless, professional edge you aim for. Additionally, choosing the right materials for your framework can greatly impact the durability and stability of the entire setup.

HOSHANHO 7 Pieces Kitchen Knife Set, Japanese High Carbon Stainless Steel Magnetic Knife Block Set, Ultra Sharp Chef Knives Sets with Ergonomic Pakkawood Handle

【Multi-purpose Knife Set】HOSHANHO 7 piece kitchen knife set includes 8" chef knife, 7" santoku knife, 7" nakiri knife,...

As an affiliate, we earn on qualifying purchases.

Surface Preparation and Finishing Touches

Before you finalize your water sheet, thorough surface preparation is crucial to achieve a smooth, professional finish. Proper cleaning removes dust, grease, and debris that could cause imperfections. Sanding the surface ensures evenness and enhances adhesion, preventing cracks or bubbles later. Applying a primer or sealant helps create a uniform base and improves the bond with finishing materials. Using a primer or sealant specifically designed for water sheets can further improve durability and appearance.

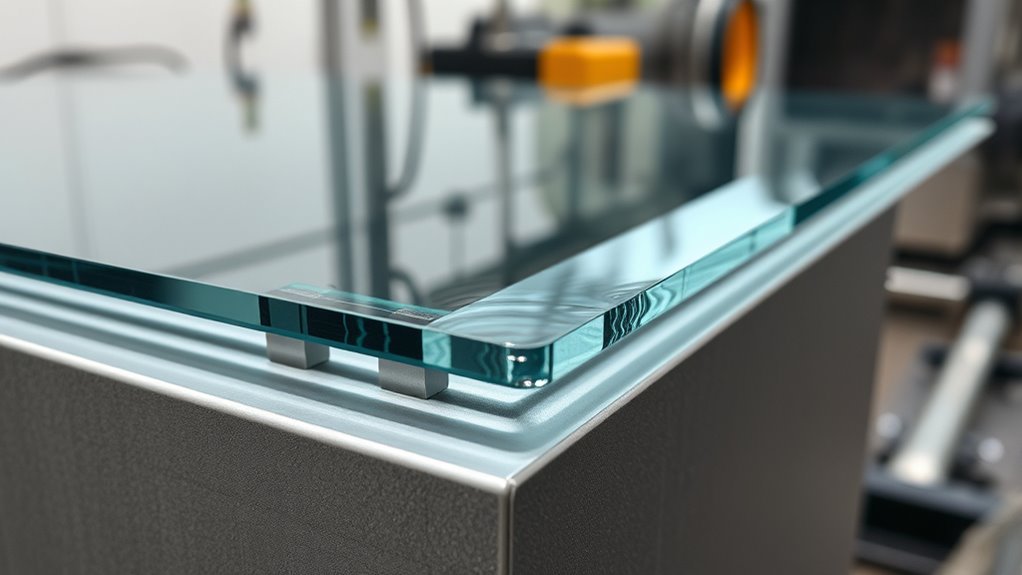

Innovations and Technologies Enhancing Edge Seamlessness

Recent advances in manufacturing and material science have revolutionized how you achieve seamless edges, making the process faster and more precise. New CNC machining techniques allow you to craft edges with micron-level accuracy, reducing errors and waste. Innovations like flexible edge banding and adhesive-free laminates ensure smooth, consistent finishes without visible joints. Advanced polymers and composites provide easier shaping and increased durability, giving you better control over edge profiles. Laser cutting and engraving technology enable you to create complex, seamless designs with minimal effort. Digital workflow software streamlines planning and execution, minimizing human error. These innovations collectively empower you to produce flawless, uniform edges that enhance the overall aesthetic and structural integrity of your water sheets efficiently. Additionally, incorporating recycled materials into edge fabrication aligns with sustainable practices, promoting eco-friendly manufacturing processes.

Frequently Asked Questions

How Do Environmental Conditions Affect Edge Perfection in Water Sheets?

Environmental conditions greatly impact edge perfection in water sheets. You need to monitor temperature, humidity, and wind, as fluctuations can cause uneven surfaces or disruptions. Wind can create turbulence, while temperature changes affect water flow and surface tension. Humidity influences evaporation rates, impacting the water sheet’s consistency. By controlling these factors during application, you guarantee a smoother, more seamless edge, achieving the desired perfection in your water sheet.

What Are Common Mistakes That Compromise Edge Seamlessness?

You might overlook small details, but that’s how cracks form in your water sheet’s edge. Common mistakes include uneven surface preparation, rushing the installation, or neglecting proper sealing. These slip-ups can cause water to leak or disrupt the seamless look. Remember, patience is key—taking your time and ensuring each step is flawless helps you achieve that perfect, uninterrupted water sheet that impresses every time.

Can DIY Methods Achieve Professional-Grade Water Sheet Edges?

DIY methods can sometimes produce decent water sheet edges, but achieving professional-grade perfection is challenging. If you lack experience, you might struggle with precise measurements, consistent application, and proper sealing, which are vital for seamless edges. While DIY can work for small projects, for flawless results, it’s better to hire professionals who have the skills, tools, and knowledge to guarantee a smooth, durable water sheet that meets high standards.

How Long Does It Typically Take to Master Edge Crafting Techniques?

It usually takes several months of consistent practice to master edge crafting techniques. You’ll need to invest time learning proper tools, techniques, and troubleshooting common issues. Expect to spend hours honing your skills, experimenting with different methods, and gaining experience with various materials. Patience is key—you’ll improve gradually as you refine your craftsmanship, but achieving flawless edges often requires dedication, persistence, and a willingness to learn from mistakes.

Are There Specific Maintenance Routines to Preserve Edge Quality Over Time?

You should regularly clean and inspect the edges to prevent buildup of debris and mineral deposits. Use gentle, non-abrasive cleaners and avoid harsh chemicals that can damage the surface. Applying a protective sealant periodically helps maintain water resistance and edge integrity. Also, address any chips or cracks promptly to prevent further deterioration. Consistent maintenance preserves the seamless look and prolongs the lifespan of your water sheet, ensuring it remains flawless over time.

Conclusion

Achieving that perfectly seamless water sheet is like tending to a delicate garden—you just need the right tools, a steady hand, and patience. When you select quality materials and pay attention to detail, every edge flows effortlessly. Embrace new innovations and don’t overlook the importance of proper support; it’s all about creating a masterpiece that feels natural and inviting. With a little care, you’ll craft an edge that everyone will admire—like a gentle breeze on a calm day.