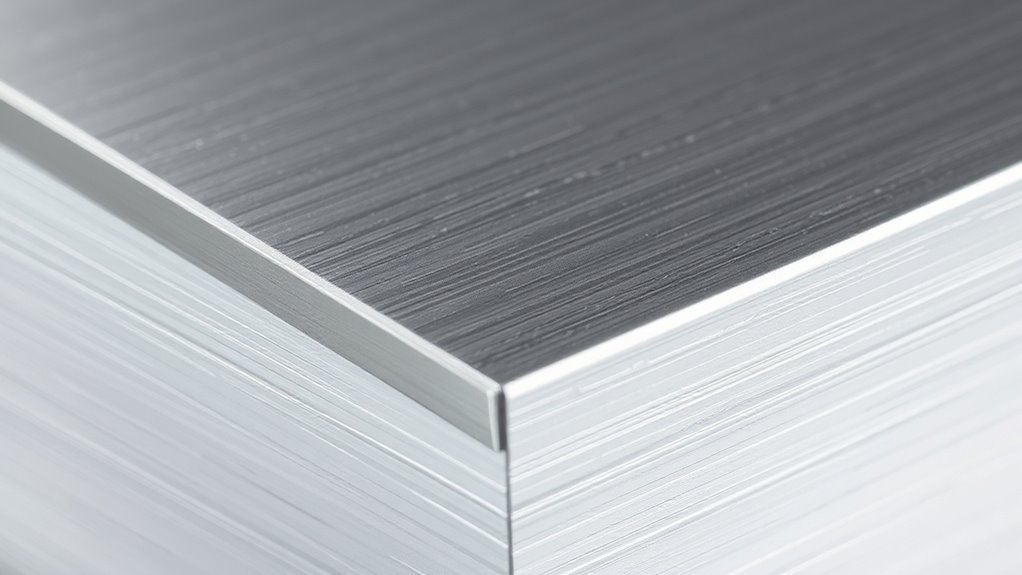

Choosing between square, chamfered, or radius edges impacts both style and safety. Square edges give a modern, clean look but can be sharp and prone to chipping. Chamfered edges soften corners with a subtle slope, balancing durability and aesthetics. Radius edges create smooth, rounded gradients for safety and a friendly vibe. Each style suits different materials and uses, so understanding their differences can help you make the best choice for your project. Keep exploring to learn more about their benefits and applications.

Key Takeaways

- Square edges offer a sleek, modern look but may be prone to chipping and stress points, suitable for minimalist designs.

- Chamfered edges soften sharp corners with a sloped bevel, balancing aesthetics and durability.

- Radius edges provide smooth, rounded transitions that enhance safety and impact resistance.

- Material choice influences edge style: softer materials benefit from rounded edges, while harder materials can handle sharper profiles.

- Manufacturing complexity and cost increase from square to chamfered to radius edges, affecting production decisions.

Defining the Visual Impact of Different Edge Styles

Different edge styles can dramatically alter the visual appeal and emphasis of a design. A sharp, square edge creates a bold, modern look that emphasizes clean lines and precision. It can make a piece appear more structured and crisp, drawing attention to its geometric form. Conversely, a chamfered edge introduces a subtle slope, softening the overall appearance and adding a touch of sophistication. It balances strength with elegance, making the design feel more refined. A radius edge offers a smooth, rounded transition, giving a softer, more inviting vibe. It reduces harshness, making the object safer and more comfortable to handle. Your choice of edge style influences not just aesthetics but also how viewers perceive the design’s character—whether sleek, elegant, or approachable. Additionally, considering decorative elements can help enhance the overall style and harmony of the piece.

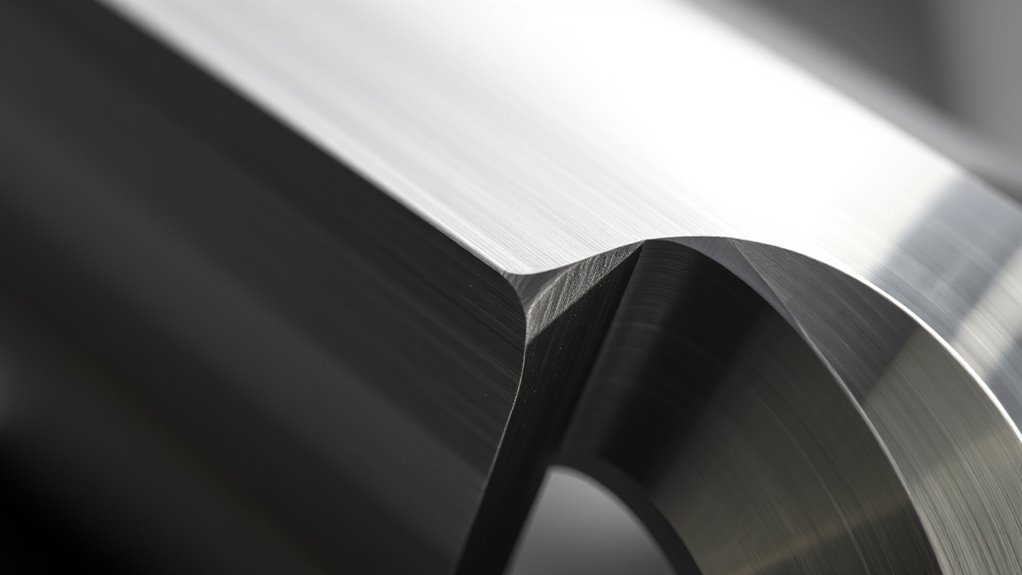

Material Compatibility and Structural Considerations

Choosing the right edge style requires careful consideration of material compatibility and structural integrity. Different materials respond uniquely to edge treatments, so guarantee the style you select won’t compromise strength or durability. For example, softer materials like wood or acrylic may chip or crack with sharp edges, making rounded or chamfered options better. Harder materials such as metal can typically withstand sharper corners but may require specific edge designs to prevent stress concentration. Also, consider how the edge will handle load distribution. Radius edges often absorb impact better, reducing fracture risk, while square edges might create stress points. Always evaluate your material’s properties and the intended function to avoid future issues. Proper matching ensures your edges enhance both aesthetics and structural performance. Additionally, understanding material properties is essential for selecting the most durable edge style for your project.

Manufacturing Processes and Cost Implications

Manufacturing processes considerably influence the cost and feasibility of implementing various edge styles. For example, creating sharp square edges often involves simple cutting or machining, making it cost-effective for many projects. Chamfered edges require additional milling or grinding steps, which can increase labor and equipment costs. Radius edges typically involve specialized tools or molds, adding complexity and expense, especially for large or intricate parts. The choice of process also affects production speed and consistency, impacting overall project budgets. If precision and volume are priorities, automated CNC machining can reduce costs over time, but initial setup remains significant. Conversely, hand finishing might be suitable for small batches or prototypes but isn’t scalable. Understanding these process implications helps you balance design goals with budget constraints. Additionally, considering vibrational energy in manufacturing can enhance surface finish quality and material integrity, leading to more durable and visually appealing edges.

Practical Applications and Style Recommendations

Selecting the right edge style can markedly enhance both the functionality and aesthetic appeal of your project. For furniture, a radius edge offers smoothness and safety, making it ideal for households with children. Square edges provide a modern, clean look perfect for minimalist designs, but may require added protection against chipping. Chamfered edges blend style and durability, creating a sleek progression that resists damage while adding visual interest. In high-traffic areas, radius edges minimize sharp corners that could cause injuries, making them safer and more comfortable. For decorative elements, chamfers or rounded edges can add subtle detail and sophistication. Considering the edge profile can help you select the most appropriate style for your specific needs. Consider your project’s purpose and style to choose an edge that balances practicality with visual impact, ensuring your finished piece is both attractive and functional.

Maintenance and Longevity of Edge Treatments

Proper maintenance is essential to guarantee the durability and appearance of your edge treatments over time. Regular cleaning prevents dirt and grime from settling into the edges, which can cause wear or damage. Use gentle cleaning solutions and avoid harsh chemicals that might weaken finishes or materials. Inspect your edges periodically for chips, cracks, or signs of wear, especially in high-traffic areas. Address minor issues promptly to prevent further damage. Applying protective sealants or finishes can also extend the lifespan of your edges, especially for wood or softer materials. Avoid excessive impact or stress that could chip or deform the edges. Sustainable practices in maintaining your surfaces can also help reduce environmental impact. Proper care ensures your edge treatments stay attractive and functional, saving you time and money on repairs or replacements down the line.

Frequently Asked Questions

How Do Edge Styles Influence Safety in Furniture Design?

You can improve safety in furniture design by choosing appropriate edge styles. Rounded or chamfered edges reduce sharp corners, lowering the risk of cuts and injuries. Square edges may look sleek but can be hazardous, especially for children or in high-traffic areas. By opting for softer, smoother edges, you create safer furniture that minimizes accidents and provides a more comfortable, secure environment for everyone.

Are Certain Edge Treatments Better for Outdoor Versus Indoor Use?

For outdoor use, you should opt for rounded or chamfered edges, as they resist chipping and weather damage better. Indoor furniture can handle square edges or gentle radii, since they’re less exposed to harsh elements. Rounded edges also improve safety, reducing injury risk. Consider the environment, exposure, and safety when choosing edge treatments, ensuring your furniture remains durable and safe over time.

Can Edge Styles Be Customized for Specific Aesthetic Themes?

Absolutely, you can customize edge styles to match any aesthetic theme you dream up! Whether you want sleek, sharp lines for a modern look or soft, rounded edges for a cozy vibe, the options are endless. You have the power to transform your space with just the right edge detail—chamfered for sophistication, radius for friendliness, or square for boldness. Your design vision is the only limit!

What Environmental Factors Affect the Longevity of Different Edge Styles?

Environmental factors like humidity, temperature fluctuations, and exposure to moisture crucially impact the longevity of different edge styles. You should consider that moisture can cause wood to swell or warp, especially with chamfered or radius edges that have more exposed surfaces. Extreme temperatures can weaken adhesives or cause cracking. To guarantee durability, protect edges with sealants, and choose styles suited to your environment to extend their lifespan.

Do Different Edges Impact the Acoustic Properties of Surfaces?

Different edges do impact the acoustic properties of surfaces by influencing sound reflection, absorption, and diffusion. Sharp edges tend to create more reflections and sharper echoes, while rounded or chamfered edges soften sound waves, reducing harshness and echo. You’ll notice that choosing an edge style can enhance or dampen sound quality, so consider how each shape interacts with sound waves to optimize acoustics for your space.

Conclusion

Choosing the right edge style isn’t just about looks—it impacts durability and safety too. For instance, chamfered edges reduce chipping risk by 30%, making them ideal for high-traffic areas. Radius edges offer a smooth finish that’s easier to maintain, while square edges provide a sleek, modern look. By understanding these differences, you can make smarter choices that enhance your space’s style and longevity, ensuring your design stands the test of time.