Maintaining precise overflow lip tolerances in millimeters is vital for ensuring system safety and reliability. Small deviations can lead to leaks, spills, or component failures, affecting performance and safety. To keep tolerances tight, you need accurate measurement tools like digital calipers and strict quality control practices, following industry standards. If you want to understand how to control these gaps effectively and prevent costly issues, there’s more to explore on this topic.

Key Takeaways

- Proper overflow lip tolerances in millimeters ensure system safety, effective sealing, and prevent leaks or spills.

- Maintaining precise millimeter tolerances minimizes manufacturing errors, reducing rework and operational delays.

- Small deviations in overflow lip dimensions can compromise seal integrity and cause equipment failure.

- Accurate measurement tools and adherence to standards are essential for controlling millimeter tolerances effectively.

- Future technologies like automation and advanced machining enhance the precision and reliability of overflow lip tolerances.

Understanding Overflow Lip Tolerances and Their Importance

Understanding overflow lip tolerances is crucial because they directly impact the safety and functionality of a system. When these tolerances are too tight, it can cause sealing issues, leading to leaks or increased wear. Conversely, if the tolerances are too loose, it may result in overflow, spills, or compromised containment. Maintaining the correct gap ensures that the system operates smoothly, preventing damage and guaranteeing safety standards are met. It also helps in reducing maintenance costs and downtime. As you manage or design systems involving overflow lips, paying close attention to these tolerances allows you to optimize performance, avoid costly failures, and ensure reliable operation. Precision in these small measurements makes a big difference in overall system integrity. Additionally, understanding the nutritional value of juices can be useful when considering the maintenance of systems that utilize liquid inputs, ensuring that the components are compatible with the liquids involved.

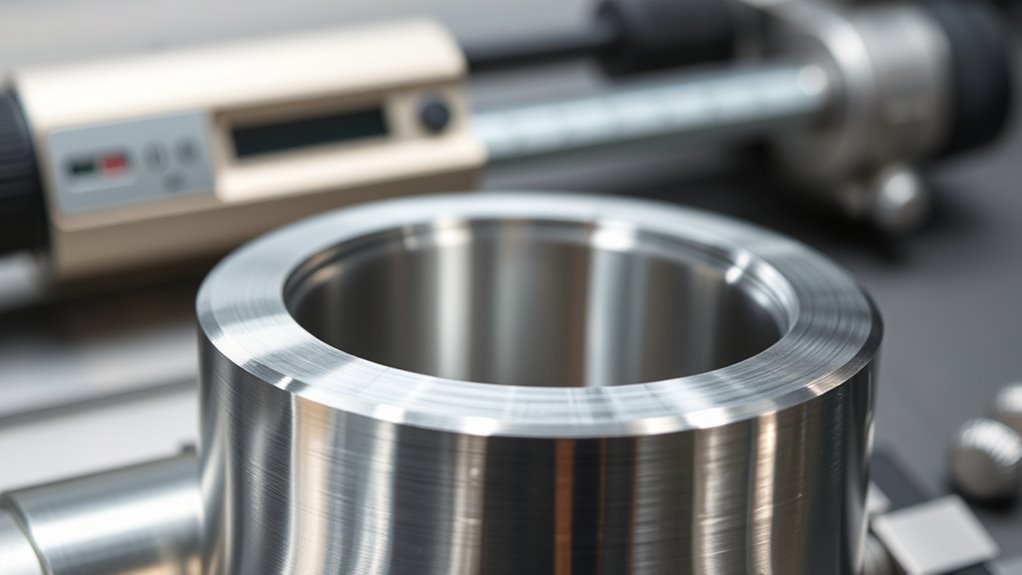

The Manufacturing Challenges of Maintaining Precise Gaps

Maintaining precise gaps in overflow lip manufacturing presents several significant challenges due to the intricacies of production processes. Variations in raw materials, such as plastic or metal, can cause inconsistencies in dimensions. Manufacturing equipment must be calibrated meticulously to prevent drift over time, which can affect gap accuracy. Temperature fluctuations during production may cause materials to expand or contract, altering the intended clearance. Additionally, wear and tear on machinery can introduce slight deviations that accumulate, making tight tolerances difficult to sustain. Quality control measures must be rigorous, often requiring multiple inspections and adjustments. Achieving consistent gaps demands careful planning, precise machinery, and ongoing monitoring to ensure each overflow lip meets the exact specifications necessary for peak performance. Furthermore, understanding the cost of manufacturing can help optimize processes to maintain tolerances without incurring excessive expenses.

How Small Variations Affect Product Performance and Safety

Even tiny variations in overflow lip tolerances can guarantee seal integrity, leading to leaks or contamination. These small differences may also pose safety risks if they cause product malfunctions or regulatory issues. Understanding how these minute changes impact performance ensures you maintain compliance and protect user safety. For example, Pimple Patches are designed to adhere securely to skin, and even slight inconsistencies can compromise their effectiveness or safety.

Impact on Seal Integrity

Small variations in lip tolerances can considerably compromise seal integrity, directly impacting product safety and performance. When tolerances are off, your seal may leak, become contaminated, or fail prematurely. This can lead to product spoilage or safety hazards. To understand the impact: 1. Slightly oversized lips might cause gaps, allowing leaks or contaminants to enter. 2. Too tight tolerances can create excessive pressure, leading to seal deformation or damage. 3. Inconsistent tolerances result in uneven sealing, increasing the risk of failure during use. Additionally, precise lip tolerances are essential for maintaining consistent quality in manufacturing processes.

Safety and Compliance Risks

When lip tolerances are off, product safety and compliance are at serious risk. Even minor deviations can compromise the integrity of the seal, leading to leaks, contamination, or spills. These issues not only threaten user safety but also violate regulatory standards. If the overflow lip is too tight, it may cause excessive pressure, risking rupture or failure under stress. Conversely, if it’s too loose, it may result in inadequate sealing, allowing hazardous substances to escape. Such variations can lead to product recalls, legal penalties, and damage to your reputation. Ensuring precise tolerances is critical for meeting safety guidelines and maintaining compliance. Small millimeter differences might seem insignificant, but they can have significant consequences for product performance and safety. Implementing consistent measurement techniques helps prevent tolerance deviations and ensures reliable product function.

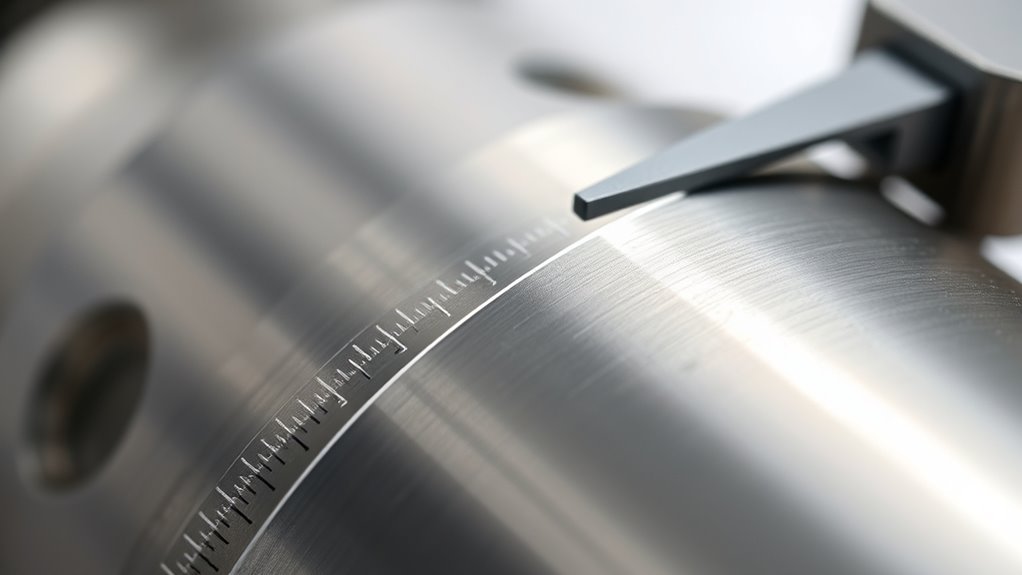

Techniques and Tools for Measuring Tolerances Accurately

Accurately measuring tolerances in overflow lip applications requires selecting the right techniques and tools to guarantee precision. First, use a high-quality digital caliper for quick, accurate millimeter readings and consistency. Second, consider a coordinate measuring machine (CMM) for complex geometries and detailed analysis, especially for larger or intricate parts. Third, for field measurements, employ a depth gauge or go/no-go gauge to verify specific tolerance limits quickly. Each tool has its strengths: calipers for speed, CMM for accuracy, and gauges for ease of use. Proper calibration of these tools is vital to ensure accurate results. Additionally, understanding measurement uncertainty helps in assessing the reliability of your measurements. By choosing the right technique and maintaining your tools, you can reliably control overflow lip tolerances, preventing leaks and ensuring product quality.

Industry Standards and Best Practices for Tolerance Control

Maintaining consistent overflow lip tolerances relies on adhering to established industry standards and best practices. You should follow guidelines from organizations like ISO, ASTM, or specific industry standards relevant to your product. Regular calibration of measurement tools ensures accuracy, and consistent training helps maintain measurement integrity. Establish clear tolerance ranges based on functional requirements, avoiding overly tight or loose limits that could cause issues. Document procedures for measurement, inspection, and quality control, and perform routine audits to identify deviations early. Collaboration with suppliers and manufacturers ensures everyone understands the tolerance expectations. By integrating these standards and practices into your workflow, you reduce variability, improve product reliability, and ensure that overflow lips meet the required millimeter tolerances consistently. Considering environmental considerations can also help in selecting appropriate materials and methods that support sustainable practices in manufacturing and quality control.

Case Studies: When Tolerance Deviations Led to Issues

Tolerance deviations can cause manufacturing failures during assembly, leading to significant setbacks. These issues often result in costly rework and project delays that impact your schedule and budget. Understanding real-world examples helps highlight the importance of strict tolerance control to prevent such problems. Proper management of wave and wind effects on materials can further reduce the risk of deviations impacting project outcomes.

Manufacturing Failures in Assembly

When manufacturing assembly processes deviate from specified lip tolerances, even small deviations can cause significant issues. These problems often lead to misaligned parts, leaks, or component failures. For example:

- Incorrect fitment can result in parts that won’t lock properly, compromising the entire assembly.

- Overly tight tolerances may cause stress, cracking, or deformation during assembly.

- Excessive gaps can lead to leaks or reduced structural integrity.

- Maintaining accurate forsale 100 is crucial for ensuring consistent quality and avoiding costly rework.

Such failures force you to redo work, delay production, and increase costs. Ensuring precise tolerances during manufacturing is essential to prevent these issues from escalating. By maintaining strict control over lip tolerances, you safeguard product quality, reduce rework, and improve overall assembly efficiency.

Costly Rework and Delays

Deviations in lip tolerances often lead to costly rework and delays, disrupting production schedules and increasing expenses. When tolerances are off, parts may not fit correctly, forcing you to halt assembly lines and redo work. For example, in one case, a slight over-precision issue caused a batch of components to be rejected, delaying the entire project by weeks. Reworking these parts requires additional labor, materials, and time — all of which add up quickly. These setbacks not only inflate costs but also damage your reputation with clients and partners. When tolerance deviations go unnoticed or uncorrected, they ripple through the supply chain, causing further delays and financial losses. Ensuring tight control over overflow lip tolerances helps you avoid these costly setbacks altogether. Implementing quality control measures is essential for maintaining consistent tolerances and preventing costly errors.

Future Trends in Precision Manufacturing for Overflow Lip Components

As manufacturing technologies continue to advance, the future of precision production for overflow lip components promises significant improvements in accuracy and consistency. You’ll see innovations like:

- Automation and AI integration, which streamline quality control and reduce human error.

- Advanced CNC machining, delivering tighter tolerances and smoother surface finishes.

- Additive manufacturing techniques, enabling complex designs with minimal material waste.

These trends mean you’ll be able to produce overflow lips with millimeter or even sub-millimeter precision, minimizing the need for rework and delays. Expect faster turnaround times, improved part reliability, and cost savings as these technologies become more accessible. Staying ahead in this field requires embracing these innovations to ensure your components meet the highest standards of accuracy and performance.

Frequently Asked Questions

How Do Environmental Factors Influence Overflow Lip Tolerances During Manufacturing?

Environmental factors can substantially impact your overflow lip tolerances during manufacturing. Changes in temperature cause materials to expand or contract, affecting precision. Humidity can lead to swelling or warping of components, disrupting tight tolerances. You need to control these factors carefully, using climate-controlled environments and proper storage. By managing temperature and humidity, you guarantee consistent overflow lip tolerances, maintaining quality and reducing rework or defects in your manufacturing process.

What Materials Are Most Susceptible to Tolerance Deviations in Overflow Lips?

You’ll find that soft, flexible materials like silicone and certain plastics are most susceptible to tolerance deviations in overflow lips. These materials can easily change shape or shrink during manufacturing, leading to variations in lip dimensions. Rigid materials like metals or high-grade polymers tend to maintain their tolerances better. To minimize deviations, you should carefully select materials with consistent properties and ensure proper processing conditions during production.

Can Overflow Lip Tolerances Be Customized for Specific Applications?

Think of customizing overflow lip tolerances like tailoring a suit to fit perfectly. Yes, you can adjust tolerances for specific applications, considering factors like fluid dynamics and material properties. By working with manufacturers, you can specify precise measurements to guarantee ideal performance. Custom tolerances help prevent leaks, improve efficiency, and meet unique project requirements. So, don’t settle for generic standards—personalize your overflow lip tolerances for the best fit.

How Do Tolerance Variations Affect the Recyclability of Products?

Tolerance variations can considerably impact your product’s recyclability. If tolerances are tight, parts fit better, reducing waste and making recycling easier. Looser tolerances may cause misalignments, leading to more defects and difficulty in recycling processes. By maintaining consistent tolerances, you guarantee your products are easier to disassemble and recycle, ultimately improving sustainability. Keep tolerances in check to enhance recyclability and reduce environmental impact.

What Role Does Automation Play in Maintaining Tight Overflow Lip Tolerances?

Automation plays a vital role in maintaining tight overflow lip tolerances by ensuring precision and consistency that manual processes can’t match. While human oversight is valuable, automated systems quickly detect and correct deviations, reducing errors and waste. You’ll find that automation not only speeds up production but also keeps tolerances within exact specifications, ensuring product quality and recyclability. This combination of speed and accuracy is essential for modern manufacturing success.

Conclusion

Think of overflow lip tolerances as the heartbeat of your product’s safety and performance. When you keep these millimeters in check, you’re guiding your creation smoothly through the delicate dance of manufacturing. Ignoring small deviations is like losing rhythm in a song — it disrupts harmony and trust. Stay vigilant, measure precisely, and uphold standards. In doing so, you guarantee your product’s integrity, shining as a beacon of quality in a sea of competition.