To prioritize safety, you should install sturdy barriers like guardrails and fencing to prevent falls and restrict access to hazards. Use alarm systems to quickly alert you to emergencies, ensuring swift responses. Select and maintain non-slip decking suited for your environment, regularly inspecting and cleaning it to prevent slips. Proper installation of these safety features and staying updated on new technologies will boost overall security—if you continue exploring, you’ll find even more effective ways to safeguard your space.

Key Takeaways

- Properly installed physical barriers prevent falls, restrict access, and contain hazards in various workplace environments.

- Effective alarm systems provide immediate alerts, enabling quick responses to emergencies and unauthorized access.

- Selecting and maintaining non-slip decking materials suited to climate and foot traffic reduces slip and fall risks.

- Regular inspection and prompt repair of barriers and decking ensure ongoing safety and compliance with standards.

- Integrating advanced alarm technologies and safety protocols enhances hazard detection and improves response times.

The Role of Physical Barriers in Workplace Safety

Physical barriers play a crucial role in maintaining safety in the workplace by preventing accidents and limiting exposure to hazards. When you install guardrails around elevated platforms, you create a physical boundary that stops falls before they happen. Safety shields around machinery protect you from moving parts or flying debris, reducing injury risks. Barriers like fencing or partitions help contain hazardous materials or restrict access to dangerous areas, ensuring only authorized personnel enter. These structures act as a first line of defense, making it easier for you to identify safe zones and stay clear of danger zones. Properly designed and maintained barriers are essential for reducing workplace accidents, safeguarding workers, and fostering a safer working environment. Additionally, understanding business regulations related to workplace safety helps ensure compliance and the effectiveness of these safety measures.

How Alarm Systems Enhance Security and Response

Alarm systems markedly boost workplace security by providing immediate alerts when unauthorized access or emergencies occur. When someone tries to breach a restricted area, the alarm activates instantly, notifying security personnel or triggering automated responses. This rapid alert helps prevent theft, vandalism, or safety hazards before they escalate. Additionally, alarm systems can be linked to emergency services, ensuring help arrives quickly if needed. You’ll find that these systems also deter potential intruders, knowing they’ll be caught early. Clear, audible alarms alert staff to dangers like fires or gas leaks, enabling swift evacuation or shutdown procedures. Overall, alarm systems act as a vigilant eye, enhancing your ability to respond promptly and effectively, ultimately creating a safer, more secure environment for everyone. Incorporating security measures such as alarms can further reinforce safety protocols and provide peace of mind.

Choosing the Right Non-Slip Materials for Decking

Are you selecting the best non-slip materials for your decking to guarantee safety and durability? First, consider the climate and foot traffic. For wet or icy conditions, textured rubber or composite materials provide excellent grip. If you want longevity, choose materials resistant to weathering, mold, and UV damage. Wood options like treated hardwood can be slip-resistant when finished properly, but they need regular maintenance. Aluminum or metal grating with anti-slip coatings also work well, especially in commercial settings. Keep in mind that surface texture, color, and ease of cleaning influence your choice. Always opt for tested, certified non-slip products to ensure safety standards are met. Proper selection reduces fall risks and extends your deck’s lifespan, keeping everyone safe and secure.

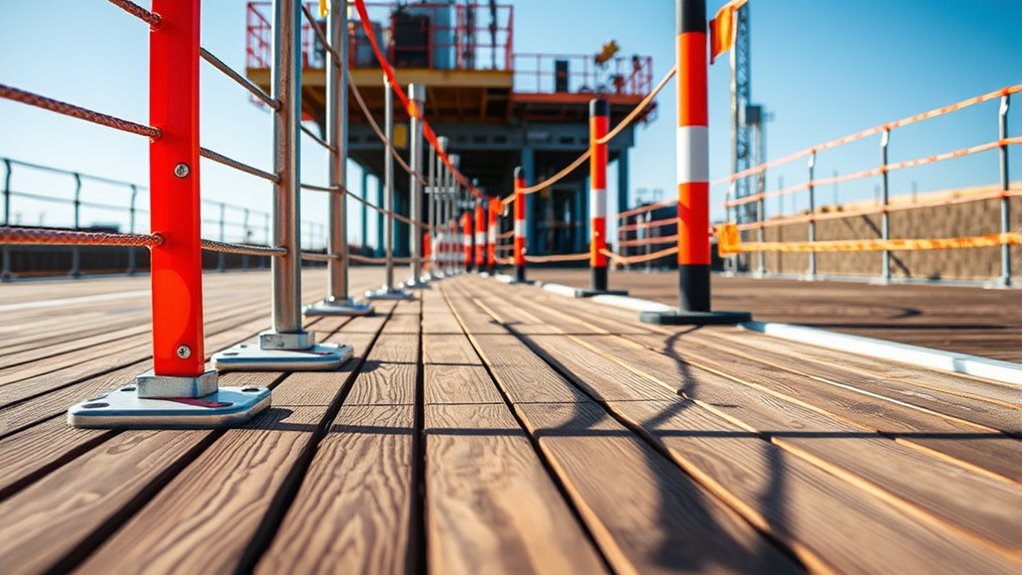

Installation Tips for Effective Safety Barriers

Proper installation of safety barriers is vital to guarantee they perform their protective function effectively. First, ensure your chosen barrier is suitable for your specific environment and meets safety standards. Securely anchor the barrier to a stable surface using appropriate fasteners, avoiding loosening over time. Check that the height and spacing comply with regulations, preventing gaps that could allow falls. Keep the barrier straight and free from damage during installation. Be cautious with existing structures—reinforce weak points if necessary. Always follow the manufacturer’s instructions for installation procedures and recommended tools. Regularly inspect the barriers after installation to confirm they remain secure and in good condition. Pinball machine weights, which vary significantly among different models, can also impact installation considerations, especially in terms of space and safety. Properly installed barriers provide reliable protection, reducing risks and ensuring safety for everyone.

Integrating Alarms With Safety Protocols

You need to understand the different alarm types and triggers to guarantee quick detection of hazards. Once alarms go off, having clear protocols for response helps minimize risks and coordinate actions effectively. Proper integration of alarms with safety protocols keeps everyone protected and reduces response times. Ensuring that alarm placement considers the layout of the space, such as a Bedroom environment, can further enhance safety measures.

Alarm Types and Triggers

How do different alarm types effectively trigger safety responses in critical situations? They do this by detecting specific hazards and alerting personnel immediately. Audible alarms, like sirens or bells, prompt quick evacuation or shutdown. Visual alarms, such as flashing lights, catch attention in noisy environments or for those with hearing impairments. Combination alarms use both for maximum effect. Some alarms are triggered manually, like panic buttons, providing instant alerts. Others activate automatically through sensors that detect smoke, gas leaks, or movement. To ensure proper responses, alarms should be:

- Clearly audible and visible

- Easy to activate manually

- Suitable for the environment

- Linked to safety protocols

- Regularly tested for dependability

- Properly maintained to prevent false alarms and ensure reliability sensor calibration

Protocols for Alarm Response

Effective alarm response relies on well-defined protocols that guarantee swift and coordinated action. When an alarm sounds, you should immediately follow established procedures, such as verifying the alert and evaluating the situation. Clear roles and responsibilities help ensure everyone knows their tasks, whether it’s alerting emergency services, shutting down equipment, or guiding personnel to safety. Training regularly with simulated drills keeps responses quick and effective. Communication is critical—use designated channels to relay accurate information and avoid confusion. Always document the incident and review the response afterward to identify improvements. Sizing and load‑planning tools can assist in preparing your safety measures and ensuring your system supports quick response times. By integrating alarms into your safety protocols, you reduce response times and minimize risks, creating a safer environment where everyone understands their role during emergencies.

Maintenance and Inspection of Non-Slip Surfaces

You need to regularly inspect non-slip surfaces to identify any wear or damage early. Keep up with cleaning and maintenance routines to guarantee these surfaces stay effective. When issues arise, follow proper repair and replacement procedures to maintain safety and prevent accidents. Incorporating preventive maintenance practices can further extend the lifespan of non-slip surfaces and ensure ongoing safety.

Regular Surface Inspections

Regular surface inspections are essential to ensuring that non-slip areas remain safe and effective. You should regularly check for signs of wear, damage, or deterioration that could compromise traction. Look for cracks, chips, or loose sections that might cause slips or falls. Pay attention to areas with high foot traffic or exposure to weather, as they tend to degrade faster. During inspections, document any issues to track recurring problems. Promptly address any hazards before accidents happen. Regular inspections help you maintain a safe environment and extend the lifespan of your non-slip surfaces. Remember to include these key points:

- Check for visible damage or cracks

- Monitor high-traffic zones

- Look for loose or worn patches

- Inspect weather-exposed areas

- Keep a detailed inspection record

- Understand the importance of proper tools to accurately assess surface conditions and perform necessary repairs.

Cleaning and Maintenance Routines

Maintaining clean and well-kept non-slip surfaces is essential for ensuring safety and prolonging their lifespan. Regularly sweep away dirt, debris, and leaves that can accumulate and obscure grip. Use a mild detergent and water to clean the surface, avoiding harsh chemicals that may damage the coating. Scrubbing with a soft-bristle brush helps remove stubborn stains or grime without harming the material. Check for any signs of wear or damage during cleaning, such as cracks or worn patches, and address them promptly. Establish a routine schedule based on foot traffic and environmental conditions to keep surfaces safe and effective. Consistent maintenance not only minimizes slip hazards but also extends the functional life of your non-slip decking. Regular inspections can also help identify wear and damage early, ensuring timely repairs and safety.

Repair and Replacement Procedures

To guarantee your non-slip surfaces remain safe and effective, it’s vital to conduct thorough inspections regularly and address any issues promptly. If you notice wear, cracks, or peeling, take immediate action to repair or replace affected areas. First, assess the extent of damage to determine whether repairs are feasible or if replacement is necessary. Then, follow these steps:

- Clean the surface thoroughly before repairs

- Remove loose or damaged material carefully

- Use appropriate repair compounds or non-slip coatings

- Allow proper curing time before use

- Replace severely damaged sections entirely

Always follow manufacturer instructions for repair products, and consider consulting a professional for extensive damage. Regular maintenance ensures your non-slip surfaces stay functional and safe, preventing slips and accidents. Additionally, understanding the importance of contrast ratio can help ensure your surfaces are clearly visible and reduce the risk of slips in various lighting conditions.

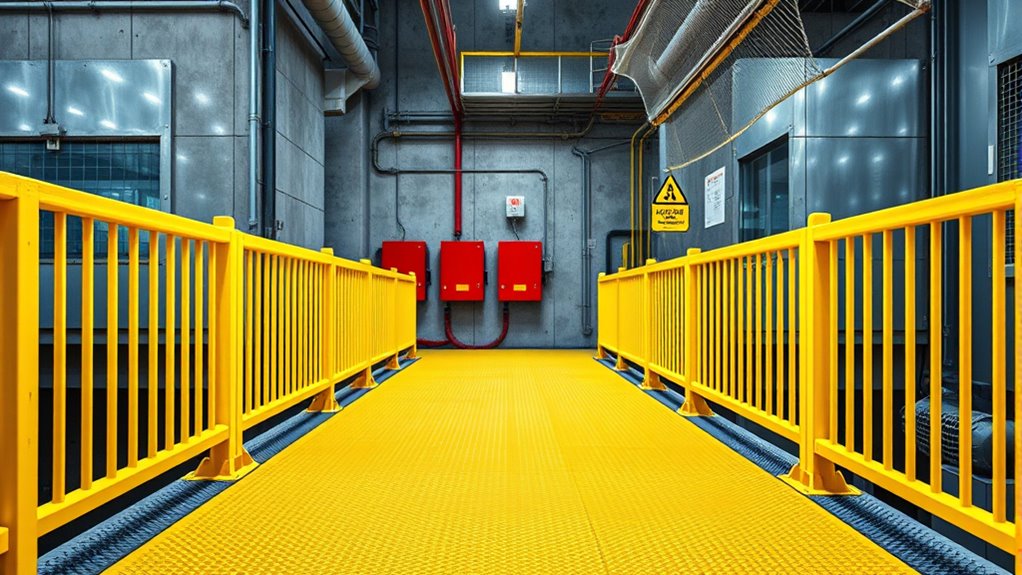

Common Types of Barriers and Their Uses

Have you ever wondered how barriers keep you safe in various environments? They serve as physical boundaries that prevent accidental falls, restrict access, or guide movement. Guardrails are common on staircases and elevated platforms, providing a sturdy barrier to stop falls. Safety fences surround hazardous areas like construction sites or chemicals, preventing unauthorized entry. Handrails offer support on ramps and stairs, reducing slip and fall risks. Glass barriers are often used in public spaces for visibility while still creating a protective boundary. Mesh barriers can block debris or debris zones temporarily. Each type is designed for specific environments and safety needs, ensuring you’re protected from potential dangers while working or moving through different spaces. Understanding their uses helps you recognize how they contribute to overall safety.

Innovative Alarm Technologies for Industrial Environments

In industrial environments, relying solely on physical barriers isn’t sufficient to guarantee safety. Innovative alarm technologies play a vital role in alerting workers to hazards before accidents happen. Modern systems use sensors, AI, and wireless communication to detect issues instantly. You can benefit from:

- Proximity sensors that trigger alerts when personnel enter dangerous zones

- Voice-activated alarms for quick, hands-free warnings

- Wireless emergency systems that notify teams remotely

- Visual alerts like flashing lights in noisy areas

- Integration with wearable devices for real-time health monitoring

These advanced alarms improve response times, reduce accidents, and create a safer workspace. By adopting these technologies, you stay proactive in preventing incidents, ensuring safety measures are immediate and effective across your operations.

Best Practices for Combining Safety Features

Combining multiple safety features effectively requires a strategic approach that maximizes their strengths and minimizes gaps. Start by evaluating your environment and identifying critical hazards. Use barriers to create physical boundaries, alarms for immediate alerts, and non-slip decking to prevent falls. Confirm these elements work together seamlessly; for instance, alarms should trigger when barriers are breached, and non-slip surfaces reduce accident risk even if alarms are delayed. Maintain clear signage and visual cues to reinforce safety messages. Regularly review and update your safety plan based on incident data and evolving conditions. Training staff on how safety features complement each other enhances overall effectiveness. By integrating these elements thoughtfully, you create a layered safety system that protects workers and minimizes risks efficiently.

Training Staff to Use Safety Equipment Effectively

Effective training is essential to guarantee your staff can operate safety equipment correctly and confidently. When your team knows how to use barriers, alarms, and non-slip decking properly, accidents decrease, and safety improves. To ensure this, provide hands-on demonstrations, clear instructions, and real-world practice. Reinforce learning with refresher courses regularly. Encourage questions to clarify doubts and prevent misuse. Consider the following tips:

- Use visual aids and step-by-step guides

- Conduct periodic safety drills

- Assign experienced staff as trainers

- Test knowledge with practical assessments

- Provide easy access to safety manuals and protocols

This approach builds competence, reduces errors, and promotes a safety culture where everyone understands their role in maintaining a secure environment. Proper training is the foundation for effective safety measures.

Frequently Asked Questions

How Do Safety Barriers Impact Overall Workplace Productivity?

Safety barriers improve your workplace productivity by preventing accidents and reducing downtime. When you install proper barriers, you minimize risks, so workers can focus on their tasks without fear. This leads to fewer injuries, less sick leave, and smoother operations. Additionally, safety barriers demonstrate your commitment to worker well-being, boosting morale and efficiency. Overall, they create a safer environment that keeps your team working effectively and consistently.

What Are the Latest Advancements in Alarm System Technology?

You’ll find that the latest alarm system tech now features AI integration for smarter, real-time threat detection. Wireless connectivity and IoT compatibility make installations easier and more flexible. Enhanced sensors detect unusual activity faster, while remote access allows you to monitor and control alarms remotely via smartphones. Additionally, some systems now include biometric access and adaptive alarm responses, providing higher security and reducing false alarms, keeping your workplace safer and more efficient.

Are There Eco-Friendly Options for Non-Slip Decking Materials?

Think of eco-friendly non-slip decking as a green thumb for your safety needs. Yes, there are sustainable options like recycled composite materials, bamboo, and cork that provide excellent slip resistance without harming the environment. These materials are durable, low-maintenance, and eco-conscious, making them perfect choices for your project. By choosing eco-friendly decking, you’re not only protecting yourself but also nurturing the planet.

How Can Safety Features Be Customized for Different Industries?

You can customize safety features for different industries by evaluating specific risks and environment needs. For example, construction sites may require more robust barriers and alarms, while food processing plants might need non-slip surfaces that are easy to sanitize. You should tailor alarm systems with industry-specific alerts and select barrier materials that withstand environmental conditions. Regular training and updates ensure safety measures stay effective and relevant to each industry’s unique hazards.

What Legal Regulations Govern Safety Barriers and Alarms?

Think of safety regulations as the backbone of your workplace. You must follow OSHA standards in the U.S., which mandate barriers, alarms, and non-slip surfaces to prevent accidents. In Europe, the EU Machinery Directive sets similar rules. Always stay updated on local, national, and industry-specific laws. By doing so, you guarantee compliance, protect workers, and avoid costly penalties. Remember, safety isn’t just a regulation; it’s a responsibility.

Conclusion

By implementing barriers, alarms, and non-slip decking, you create a safer workspace that protects everyone. Some might think these measures are costly or cumbersome, but the investment pays off by preventing accidents and saving lives. With proper training and smart choices, safety features become seamless parts of your daily routine. Don’t let hesitation hold you back—prioritize safety, and you’ll foster a secure environment where everyone can work confidently and efficiently.