Using variable-speed pumps helps you save energy by adjusting motor speed to match your process demands. They provide precise flow control without sacrificing sheet quality or efficiency. By responding instantly to changes, they reduce energy waste and minimize equipment wear. This technology also offers long-term cost savings and enhances system reliability. To discover how you can maximize these benefits while maintaining top sheet standards, explore the full potential of variable-speed pumps here.

Key Takeaways

- Variable-speed pumps adjust motor speed in real-time to match process demands, ensuring energy is used efficiently without sacrificing performance.

- They eliminate the need for throttling valves, reducing energy waste and maintaining consistent pressure and flow.

- Implementing these pumps can lead to significant energy savings, often up to 30%, without compromising system reliability.

- Proper selection and maintenance of variable-speed pumps optimize energy efficiency while preventing process disruptions.

- Integration of advanced controls and IoT technology enables continuous system monitoring, further enhancing energy savings and operational stability.

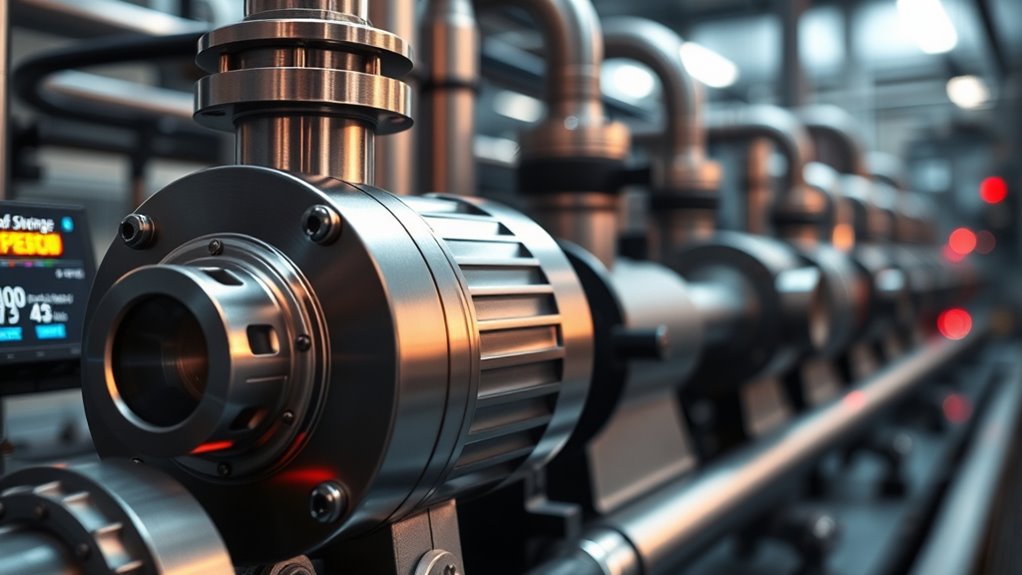

How Variable-Speed Pumps Function in Manufacturing

Variable-speed pumps adjust their motor speed to match the flow requirements of a process, which allows for greater control and efficiency. When your process demands less flow, the pump slows down, reducing energy consumption and wear. Conversely, if higher flow is needed, the pump speeds up accordingly. This dynamic adjustment is achieved through electronic controllers that monitor system pressure and flow, sending signals to modify the motor’s speed in real time. As a result, you can maintain precise pressure and flow rates without relying on throttling valves, which waste energy. This responsive operation helps optimize your manufacturing process, ensuring consistent performance while minimizing power use. By adapting to changing demands, variable-speed pumps keep your system running smoothly and efficiently. Additionally, precise control over flow rates can help reduce the likelihood of system overloads and improve overall process stability.

The Advantages of Implementing Variable-Speed Pump Technology

Implementing variable-speed pump technology offers you significant energy savings by adjusting output to match demand. You also gain precise flow control, ensuring ideal performance for your processes. Additionally, these pumps help reduce operational costs over time by improving efficiency and reducing wear. Incorporating dynamic control systems can further optimize pump performance and adapt to changing conditions for even greater energy savings.

Energy Efficiency Gains

Since pumps often operate at fixed speeds regardless of demand, they tend to waste energy when full power isn’t needed. By switching to variable-speed pump technology, you can optimize energy use, matching output precisely to system needs. This adjustment reduces unnecessary power consumption, leading to significant energy savings. You’ll notice lower electricity bills and a smaller carbon footprint. Additionally, variable-speed pumps minimize wear and tear because they avoid abrupt starts and stops, extending equipment lifespan. This efficiency gain helps you operate more sustainably without sacrificing performance. Moreover, understanding energy efficiency principles can further enhance your ability to optimize system operation. Overall, implementing variable-speed pumps allows you to cut energy costs, reduce environmental impact, and improve system reliability—all while maintaining the quality of your sheet production.

Precise Flow Control

By adjusting the pump’s speed in real-time, you can achieve highly accurate flow control that matches your system’s exact requirements. This precise regulation ensures your process runs smoothly without over or under-supplying fluid. With variable-speed pumps, you can respond instantly to fluctuations in demand, maintaining consistent pressure and flow rates. This level of control minimizes waste and prevents issues like pressure surges or flow disruptions that can affect product quality. Unlike fixed-speed pumps, which operate at a constant setting regardless of need, variable-speed models adapt seamlessly, giving you maximum performance at all times. This precision not only improves system reliability but also enhances overall process stability, making sure your operations stay efficient and effective every step of the way. Incorporating pressure regulation features can further optimize your system’s performance and longevity.

Reduced Operational Costs

Switching to variable-speed pump technology can considerably cut your operational costs. By adjusting pump speed to match real-time demand, you avoid wasting energy on unnecessary flow rates. This means you’ll reduce electricity bills and lower wear-and-tear on the equipment, leading to fewer maintenance costs. Additionally, variable-speed pumps operate more efficiently across varying loads, preventing sudden power surges and minimizing energy peaks. Properly calibrated settings ensure optimal performance and further enhance energy savings. Over time, these savings add up markedly, making your operations more economical. Plus, since these pumps are designed to optimize performance, you’ll experience fewer breakdowns and downtime. Overall, implementing variable-speed pump technology helps you run your facility more cost-effectively, ensuring better resource management and a healthier bottom line.

Comparing Fixed-Speed and Variable-Speed Pump Systems

When choosing between fixed-speed and variable-speed pump systems, understanding their fundamental differences is essential. Fixed-speed pumps operate at a constant speed, providing steady flow regardless of demand. They turn on and off as needed, which can lead to inefficiencies during low-demand periods. In contrast, variable-speed pumps adjust their motor speed based on real-time requirements, delivering only the flow needed at any moment. This flexibility reduces energy consumption and minimizes wear and tear. Fixed-speed systems are simpler and usually less expensive upfront, but they often cost more over time due to higher energy use. Variable-speed pumps, while more complex initially, offer better control and significant energy savings, making them a smarter choice for many applications. Additionally, the ability of tuning modifications to enhance vehicle performance demonstrates the importance of precise adjustments in optimizing efficiency and function.

Energy Savings Potential With Variable-Speed Pumps

Variable-speed pumps can considerably reduce energy consumption compared to fixed-speed systems, especially in applications with variable flow demands. By adjusting pump speed to match real-time requirements, you prevent unnecessary energy use during low-demand periods. This precise control minimizes pump operation at full capacity when it’s not needed, leading to significant energy savings. Studies show that variable-speed pumps can cut energy costs by up to 50% in certain operations. Additionally, because they operate more efficiently across a range of flow rates, you reduce wear and tear on equipment, lowering maintenance costs over time. Incorporating water system efficiency measures such as variable-speed pumps can be a key step in achieving sustainable water management. Overall, implementing variable-speed technology offers a practical way to optimize energy use, reduce operational expenses, and improve sustainability without compromising process performance.

Impact on Sheet Quality and Process Control

Implementing variable-speed pumps directly enhances sheet quality and process control by enabling more precise regulation of flow rates and pressure. This precision helps you maintain consistent paper thickness and surface smoothness, reducing defects caused by fluctuations. With better control, you can respond swiftly to changes in production requirements, ensuring stable operations throughout the process. Variable-speed pumps also minimize sudden pressure surges, preventing damage to sensitive equipment and improving overall process stability. As a result, your production runs become more predictable, and quality consistency improves. This fine-tuned control allows you to optimize each stage, reducing waste and rework. Regular maintenance and monitoring vendor reliability are essential to ensure the continued efficiency of these systems. Ultimately, incorporating these pumps helps you produce superior sheets while maintaining tight control over your process parameters.

Key Factors to Consider When Choosing a Variable-Speed Pump

Choosing the right variable-speed pump requires careful consideration of several key factors to guarantee it meets your specific process needs. First, assess your flow rate requirements—ensuring the pump can handle peak demands without overworking. Second, consider energy efficiency; selecting a model with a high turndown ratio maximizes savings and adaptability. Third, evaluate the pump’s control capabilities; advanced controls can optimize performance and reduce waste. Additionally, utilizing AI in Business technologies can help optimize pump operation and maintenance schedules, leading to further efficiency. These factors directly impact your operational costs, product quality, and energy consumption. By focusing on these essentials, you assure your investment delivers reliable performance and significant energy savings. Remember, the right pump isn’t just about specifications—it’s about matching its capabilities with your process goals to achieve ideal results.

Maintenance and Operational Considerations

Proper maintenance and operational practices are essential to guarantee your variable-speed pump performs reliably and efficiently over time. Regularly inspect and clean filters, strainers, and cooling systems to prevent blockages and overheating. Monitor pump performance and energy consumption to catch issues early. Keep an eye on vibration levels and unusual noises, which can indicate bearing or impeller problems. Ensure sensors and control systems are calibrated correctly for accurate operation. Lubricate moving parts as recommended by the manufacturer to reduce wear. Always follow safety protocols when servicing the pump. Adjust operating parameters carefully to avoid unnecessary stress on components. Proper training for operators helps guarantee best practices are followed, prolonging equipment lifespan and maintaining energy savings. Additionally, understanding Kia Tuning options can optimize performance and efficiency of related vehicle components.

Real-World Examples of Energy Efficiency Gains

Real-world examples show how variable-speed pumps can notably cut energy costs across various sectors. You’ll see notable savings in industrial plants, water treatment facilities, and HVAC systems. These successes demonstrate the tangible benefits of adopting energy-efficient pump technologies.

Industrial Plant Savings

Have you ever wondered how industrial plants can substantially cut energy costs? Implementing variable-speed pumps has led to impressive savings. For example:

- A manufacturing facility reduced energy bills by 30% within a year, simply by optimizing pump operation.

- An automotive plant saved over $200,000 annually by switching to variable-speed systems, directly impacting profit margins.

- A food processing plant decreased energy consumption by 25%, ensuring sustainability goals were met without sacrificing productivity.

These real-world examples show that upgrading to variable-speed pumps doesn’t just cut costs—it boosts efficiency and competitiveness. By tailoring pump speeds to actual demand, you avoid waste and maximize energy use. The results are clear: lower expenses, improved environmental impact, and a stronger bottom line.

Water Treatment Efficiency

Implementing variable-speed pumps in water treatment plants has proven to substantially boost energy efficiency. By adjusting motor speed to match real-time demand, you reduce unnecessary energy consumption. For example, a municipal water facility that switched to VFDs saw a 25% decrease in energy use during peak hours and even higher savings during variable flow conditions. Similarly, a large industrial plant reported cutting its pump energy costs by nearly 30%, simply by optimizing pump operation with variable-speed technology. These improvements not only lower utility bills but also extend equipment lifespan by preventing overworking. You’ll find that fine-tuning pump speeds to process flow requirements ensures consistent water quality and reliable operation, all while significantly reducing energy waste and environmental impact.

HVAC Energy Reductions

How much can you save on energy costs by optimizing your HVAC systems? The answer might surprise you. Implementing variable-speed pumps and smart controls can lead to significant reductions.

Here are some real-world results:

- A commercial building cut energy bills by 30% after upgrading to variable-speed HVAC components.

- A manufacturing plant reduced its peak energy demand by 40%, preventing costly peak-hour charges.

- A school district saw a 25% decrease in cooling and heating costs within the first year.

These examples show how optimizing your HVAC system isn’t just eco-friendly—it’s financially smart. You can enjoy lower energy bills, reduce your carbon footprint, and maintain comfortable environments without sacrificing performance. Small changes lead to big savings.

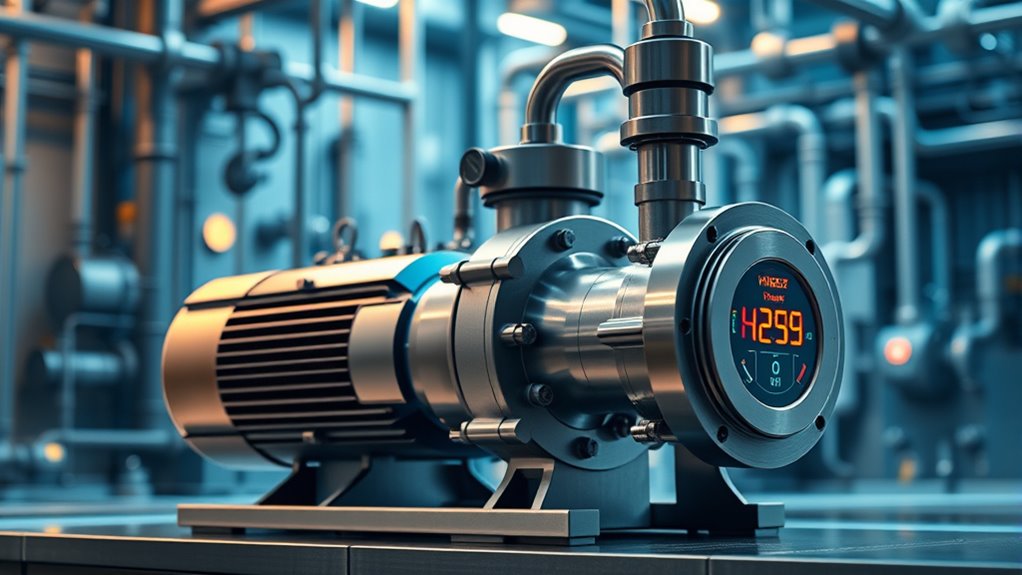

Future Trends and Innovations in Pump Technology

As technology advances, the future of variable-speed pump systems promises significant improvements in efficiency, control, and sustainability. Expect smarter pumps integrated with IoT devices, enabling real-time monitoring and predictive maintenance. These innovations will optimize energy use, reduce downtime, and extend equipment lifespan. Advances in motor design, such as permanent magnet motors, will boost efficiency further. Additionally, innovations in materials and sealing technologies will improve durability and reduce leaks. Artificial intelligence and machine learning will allow pumps to adapt automatically to changing system demands, maximizing performance while conserving energy. Sustainability will also be prioritized, with eco-friendly materials and energy recovery systems becoming standard. Overall, these trends will make variable-speed pumps more intelligent, reliable, and environmentally friendly, helping you cut costs and meet future energy efficiency goals.

Frequently Asked Questions

What Are the Initial Costs of Installing Variable-Speed Pumps?

The initial costs of installing variable-speed pumps typically range from moderate to high, depending on system size and complexity. You might spend more upfront compared to traditional pumps due to the advanced technology and control systems involved. However, these costs often offset long-term savings through reduced energy consumption and maintenance. To get an accurate estimate, consider consulting with suppliers or contractors who can evaluate your specific needs and project scope.

How Do Variable-Speed Pumps Affect Overall Plant Maintenance?

You’ll find that variable-speed pumps can simplify your plant maintenance by reducing wear and tear on equipment, since they operate more smoothly and adapt to changing demands. They often require less frequent servicing and help prevent issues like cavitation or overpressure. However, you’ll need to stay vigilant with their electronic components and control systems, which may require specialized training or troubleshooting skills to keep everything running efficiently.

Are There Specific Industries That Benefit Most From This Technology?

You’ll find the most benefit from variable-speed pumps in industries like water treatment, HVAC, and manufacturing. These sectors require precise flow control and energy efficiency, making the technology ideal. You’ll notice reduced energy costs, less wear and tear, and improved process stability. Implementing variable-speed pumps helps you save money and enhance operational performance, especially where fluid handling varies frequently or demands tight control.

How Do Variable-Speed Pumps Integrate With Existing Automation Systems?

You’ll love how easily variable-speed pumps integrate with your automation systems, making your operations smoother than ever. They connect seamlessly through standard communication protocols like Ethernet/IP, Modbus, or Profibus, allowing real-time adjustments and precise control. This integration turbocharges your efficiency, reduces energy waste, and simplifies management. With just a few tweaks, your entire system becomes smarter, more responsive, and ready to handle any challenge with effortless precision.

What Are the Common Challenges Faced During Implementation?

You might face challenges like integrating new pumps with your existing automation system, which can involve compatibility issues or outdated hardware. You could also encounter resistance from staff unfamiliar with the technology, leading to training needs. Ensuring proper calibration and control settings takes time, and unforeseen technical glitches may arise. To overcome these, plan thoroughly, involve experienced technicians, and allocate resources for training and troubleshooting.

Conclusion

By switching to variable-speed pumps, you can cut energy costs by up to 50%, making your manufacturing process more efficient and eco-friendly. Imagine saving enough energy to power a small household—it’s like giving your operation a green boost while improving sheet quality. Embracing this technology not only reduces expenses but also enhances process control, helping you stay ahead in competitive markets. Don’t miss out on these powerful benefits—your future efficiency depends on it.