To size your pumps at network edges, first define your required flow rate based on system demand and future growth. Then, calculate the total head to overcome friction, elevation, and pressure needs. It is crucial to include redundancy—using backup pumps or multiple units—to ensure reliable operation during failures or peak periods. Proper selection balances efficiency, capacity, and space constraints. Keep these points in mind, and you’ll develop a robust, reliable pump setup that meets your system’s needs.

Key Takeaways

- Determine peak and average flow requirements based on edge system demands and future scalability needs.

- Calculate total dynamic head (TDH) considering elevation, friction, fittings, and pressure losses for accurate pump sizing.

- Incorporate redundancy by selecting multiple pumps or standby units to ensure continuous operation during failures.

- Match pump type and capacity to system pressure, flow rates, and environmental constraints for optimal performance.

- Implement monitoring and control systems for real-time performance tracking, maintenance planning, and operational flexibility.

Understanding System Requirements at the Edge

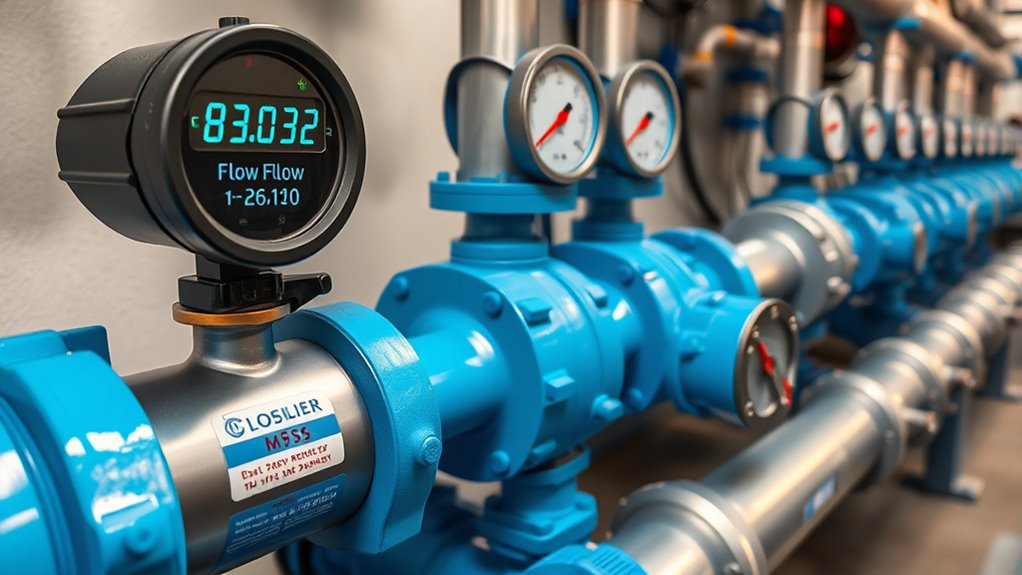

To properly size a pump for edge applications, you first need to understand the specific system requirements. This means identifying what the system needs to operate effectively, including pressure levels, flow rates, and the type of fluid involved. You should also consider environmental factors like temperature, potential obstructions, and space constraints that could influence pump performance. Knowing the system’s operational goals helps determine the necessary pump capacity and durability. Additionally, assess any safety or redundancy considerations, ensuring the pump can handle peak demands or unexpected failures. Gathering detailed information about your system’s demands allows you to select a pump that meets performance needs without over- or under-sizing, ultimately ensuring efficiency and longevity at the edge. Understanding the system requirements thoroughly ensures optimal pump performance and longevity.

Calculating Appropriate Flow Rates for Your Application

Determining the right flow rate is essential to guarantee your pump meets your system’s needs without wasting energy or risking damage. To do this, start by analyzing your application’s requirements, including the volume of fluid you need to move over a specific period. Consider peak demand times to ensure your system can handle fluctuations. Measure the flow rates of existing systems or consult technical specifications for similar setups. Use these data points to establish a target flow rate that balances efficiency and performance. Avoid oversizing, which wastes energy, or undersizing, which hampers operation. Make adjustments based on real-world conditions and future growth projections. Accurate flow calculations guarantee your pump operates reliably, efficiently, and with minimal risk of failure or unnecessary energy consumption. Additionally, understanding your electric power generation needs can help optimize overall system efficiency and sustainability.

Determining Necessary System Head and Pressure

To choose the right pump, you need to determine the system head and pressure required for your application. This involves calculating the total head needed to overcome friction losses and elevation changes. Ensuring adequate pressure guarantees your system operates efficiently and reliably. Additionally, considering potential system failures can help in designing a more resilient pumping setup.

Calculating System Head

Have you ever wondered how much head pressure your pump needs to guarantee proper flow? Calculating system head involves understanding the total height your pump must overcome, including friction losses and elevation changes. To determine this, consider:

- The vertical distance from the pump to the highest point in the system

- Friction losses caused by pipes, fittings, and valves

- Changes in pipe diameter that affect flow resistance

- Any additional pressure needed for equipment or process requirements

- The flow rate required to meet system demands, which influences the head calculation

Accurately evaluating these factors ensures your pump can deliver consistent flow without underperforming or overworking. Missing this step can lead to insufficient pressure, system inefficiencies, or equipment damage. Precise calculation of system head keeps your system reliable and efficiently functioning.

Ensuring Adequate Pressure

Ensuring adequate pressure in your system starts with accurately evaluating the required system head. You need to determine the total dynamic head (TDH) that accounts for elevation changes, pipe friction, fittings, and other losses. Measure or estimate the elevation difference between the pump and the highest point in your system. Consider flow rates and the pressure needed at outlets to meet your demands. Use these factors to calculate the total head your pump must deliver. This guarantees the system maintains proper pressure throughout, preventing issues like insufficient flow or pressure drops. By precisely assessing your system’s head requirements, you select a pump that provides reliable performance, maintains consistent pressure, and avoids over- or under-sizing, which can lead to inefficiencies or equipment failure. Proper system sizing is essential to optimize energy efficiency and ensure the longevity of your equipment.

Ensuring Redundancy for Reliability and Uptime

To keep your system reliable and minimize downtime, you should consider implementing multiple pump configurations and automatic switching. These setups guarantee continuous operation even if one pump fails. Regular maintenance checks are also essential to catch issues early and maintain peak performance. Incorporating redundancy strategies can further enhance system resilience and reduce the risk of failure.

Multiple Pump Configurations

Implementing multiple pump configurations is essential for maintaining reliable operation and minimizing downtime. By using more than one pump, you ensure continuous flow even if one unit needs maintenance or fails unexpectedly. This setup provides peace of mind, reduces operational interruptions, and safeguards your system’s uptime. Consider these key benefits:

- Uninterrupted service, preventing costly shutdowns

- Enhanced system resilience, ready for unexpected failures

- Flexibility in operation, matching demand fluctuations

- Extended equipment lifespan, reducing wear and tear

- Adaptability to changing conditions allows your system to respond efficiently to operational demands and unexpected events.

Multiple pump configurations enable you to adapt quickly and keep your system running smoothly. They provide a safety net, allowing maintenance without halting operations. This approach guarantees your system remains dependable, efficient, and capable of handling peak demands at all times.

Automatic Pump Switching

Automatic pump switching plays a essential role in maintaining system reliability by automatically redirecting flow to standby pumps when primary units fail or require maintenance. This process minimizes downtime and ensures continuous operation, critical in systems demanding high uptime. By monitoring pump performance and system pressure, automatic switches activate seamlessly, preventing flow interruptions. Properly configured switching allows you to maintain redundancy without manual intervention, reducing risks of overload and system failure. Consider this overview of switching strategies:

| Strategy | Activation Trigger | Benefits |

|---|---|---|

| Time-based | Scheduled intervals | Predictable redundancy |

| Load-based | Flow/pressure drops | Responsive to demand |

| Manual override | Operator initiation | Flexibility for maintenance |

Implementing these strategies ensures your system stays operational, reliable, and resilient. Additionally, understanding the signs of spoilage in components like pump fluids can help prevent unexpected failures and maintain system integrity.

Regular Maintenance Checks

Regular maintenance checks are essential for ensuring your pump system remains reliable and minimizes downtime. When you stay proactive, you catch issues early before they cause costly failures. Regular inspections help you identify worn parts, leaks, or unusual noises that signal trouble. This proactive approach can also help prevent clogged mechanisms that may result from debris accumulation or design flaws, which keeps your system running smoothly and maintains your edge.

Remember, neglecting maintenance can lead to:

- Unexpected breakdowns disrupting your operations

- Emergency repairs that drain resources

- Reduced pump lifespan and efficiency

- Loss of confidence in your system’s performance

Selecting the Right Pump Type and Efficiency Considerations

Choosing the right pump type is crucial for ensuring efficient and reliable edge operations. You need to select a pump that matches your flow needs, system pressure, and space constraints. Consider whether a centrifugal, vertical, or submersible pump best fits your setup. Each type offers different efficiencies and maintenance requirements, impacting long-term costs. Efficiency is key; high-efficiency pumps save energy and reduce operational expenses. Evaluate the pump’s performance curves, energy consumption, and lifespan before committing. Here’s a quick comparison:

| Pump Type | Efficiency Level | Best for |

|---|---|---|

| Centrifugal | Moderate to high | Large flow, low head demand |

| Vertical | High | Space-limited or deep wells |

| Submersible | Very high | Underwater or flooded areas |

Selecting the right type optimizes performance and minimizes costs. Considering hybrid bike versatility can inform your choice of equipment to match diverse operational needs.

Integrating Control and Monitoring for Optimal Performance

Integrating control and monitoring systems into your pump setup is essential for achieving ideal performance and efficiency. When done right, you’ll gain real-time insights, prevent costly failures, and optimize energy use. These systems empower you to respond quickly to changing conditions, ensuring your operation stays smooth and reliable. Imagine the confidence of knowing your pump is always performing at its best, with minimal downtime and maximum lifespan. You’ll feel assured knowing you can identify issues before they escalate, saving money and reducing stress.

- Detect problems early, avoiding costly repairs

- Adjust flow and pressure instantly for peak efficiency

- Track performance data to plan maintenance proactively

- Gain peace of mind with automated alerts and diagnostics

Practical Tips for Implementation and Future Scalability

To guarantee your pump system is both effective now and adaptable for future growth, start by selecting scalable control and monitoring solutions that can expand with your operations. Choose modular components and open communication protocols to simplify upgrades and integration. Document your system’s current capacity and anticipate future demands, ensuring your equipment can handle increased flow or head requirements without complete replacement. Prioritize flexible piping layouts and easily accessible maintenance points to streamline expansion. Invest in automation that allows remote adjustments and real-time data analysis, enabling quick responses to changing conditions. Regularly review your system’s performance and plan incremental upgrades rather than major overhauls. This proactive approach ensures your pump system remains reliable, efficient, and ready for growth.

Frequently Asked Questions

How Does Ambient Temperature Affect Pump Performance at the Edge?

Ambient temperature directly impacts your pump’s performance by affecting fluid viscosity and material durability. As temperatures rise, fluids become less viscous, potentially increasing flow rates and reducing head. Conversely, colder temperatures can raise viscosity, decreasing flow efficiency. High temperatures may also cause equipment overheating or material degradation. To guarantee ideal operation at the edge, you should select pumps rated for the expected temperature conditions and consider cooling or insulation to maintain performance.

What Are the Best Practices for Reducing Energy Consumption?

Imagine your pump as a diligent traveler, using energy wisely to reach its destination. To cut energy use, you should select the right-sized pump, avoid oversized units, and maintain it properly. Use variable frequency drives to match demand, insulate pipes to reduce losses, and schedule operation during off-peak hours. These steps help your pump work efficiently, saving energy like a savvy traveler conserving resources on a long journey.

How Can Vibration Analysis Predict Pump Failures?

Vibration analysis helps you predict pump failures by detecting irregularities early. You can identify abnormal vibrations caused by misalignment, imbalance, or bearing wear before they lead to breakdowns. Regular monitoring allows you to spot trends and fluctuations in vibration levels, enabling you to take proactive maintenance actions. This reduces downtime, extends equipment life, and saves you money by preventing unexpected failures and costly repairs.

What Are Cost-Effective Options for Small-Scale Edge Pump Systems?

You’ll find that choosing efficient, reliable options saves money in the long run. Opt for small, energy-efficient pumps with variable speed drives to adapt flow needs. Consider modular systems that allow easy expansion or maintenance, minimizing downtime. Using durable materials and pre-approved components reduces replacement costs. Investing in proper sizing and quality guarantees smooth operation, preventing costly failures, and providing a cost-effective solution tailored to your small-scale edge pump system needs.

How to Plan for Future Capacity Increases in Edge Pump Design?

To plan for future capacity increases, you should select a pump with a slightly higher flow and head capacity than your current needs. Incorporate modular or scalable systems that allow easy upgrades or additions. Consider installing variable frequency drives to adjust performance as demand grows. Regularly review system performance and stay informed about new technologies, ensuring your pump setup remains flexible and cost-effective for future expansion.

Conclusion

By properly sizing your edge pumps, you guarantee reliable operation and avoid costly downtime. Did you know that inadequate pump sizing can lead to energy waste of up to 30%? Taking the time to understand your system’s flow, head, and redundancy needs not only boosts efficiency but also extends equipment lifespan. With the right approach, you’ll optimize performance today and scale confidently for future demands, saving you money and headaches down the line.